{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

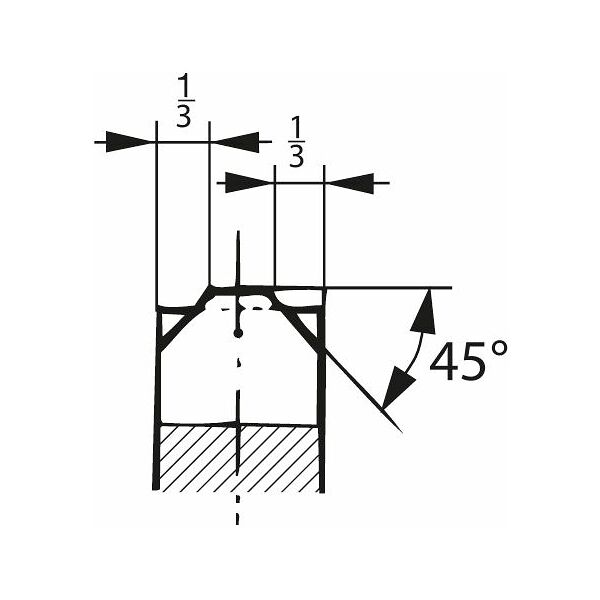

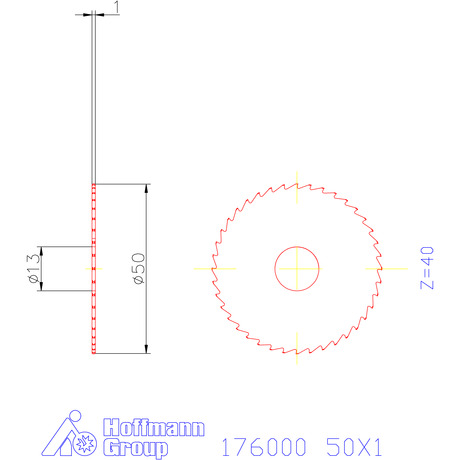

| ⌀ | 50 mm | |

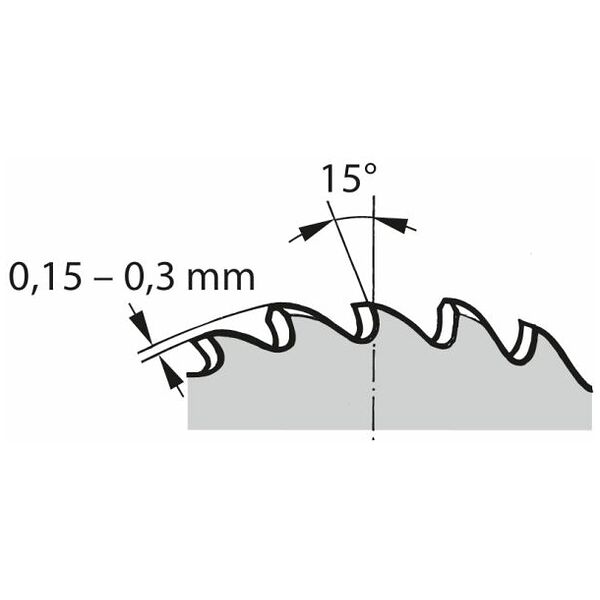

| Thickness | 1 mm | |

| Coating | uncoated | |

| Tool material | HSS | |

| Standard | DIN 1838 | |

| Bore ⌀ | 13 mm | |

| No. of teeth Z | 40 | |

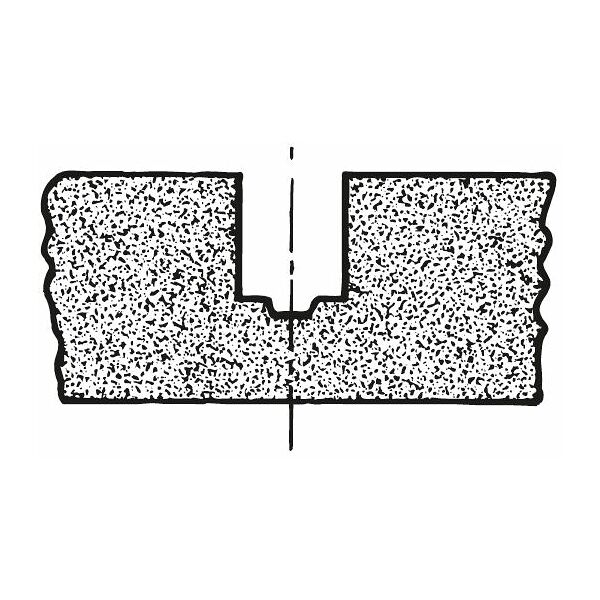

| maximum cutting depth | 12.75 mm | |

| Suitable for material | Metal | |

| Through-coolant | no | |

| Type of product | Circular saw blade |

| Article number |

176000 50X1

Copy |

|

| EAN / GTIN |

4045197244253

Copy |

|

| Manufacturer | Re-Bo REBER GmbH Spezialfabrik für Metallkreissäge, Ellwanger Straße 97, 73441 BOPFINGEN, Germany, www.re-bo.com |