{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

| maximum torque | 2,000 Nm | |

| Direction of tightening | Right-hand tightening | |

| Torque measuring accuracy | ±3 % | |

| Test certificate | Manufacturer’s test certificate | |

| Series | DREMOMETER | |

| Overall length L | 2,353 mm | |

| Torque range | 750 Nm - 2,000 Nm | |

| Scale graduation, 1 graduation = | 50 Nm | |

| Weight | 11,600 g | |

| Square drive | 1 in | |

| Display | analogue | |

| Release signalling | acoustic; haptisk | |

| Trigger principle | mechanical short-travel release | |

| Connection format | Push-through square drive (ratchet) | |

| Measurement technology | mechanical | |

| Data can be recorded | no | |

| Setting the trigger value | with adjustment scale | |

| Feedback | triggering | |

| Reversible reading | Nm | |

| Measurement process | Torque | |

| Adjustable trigger value | adjustable | |

| Standard | DIN EN ISO 6789 | |

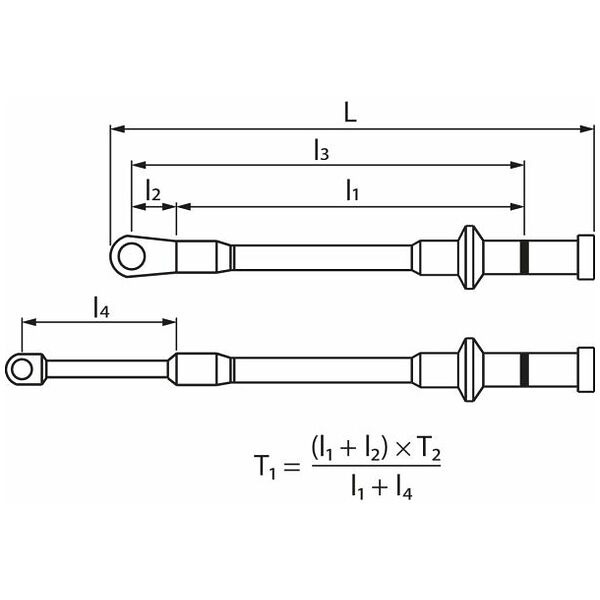

| Lever length without plug-in head [l1] | 2,213 mm | |

| Lever length including factory calibration reference dimension [l3] | 2,213 mm | |

| Type of product | Torque Wrench |

| Article number | 657000 2000 | |

| EAN / GTIN | 4002805856413 | |

| Manufacturer number | 7695250 |