Perfect profiles - Producing inner and outer profiles in seconds

GARANT profile spaces on the lathe

Profile broaching (also: tumbling) is a machining process. In profile broaching, a profile broaching insert is used to produce the desired profile (hexagonal, square or special profiles) in one operation by means of a concentric movement.

Always the right system for economical production of internal and external profiles:

With a complete range for broaching profiles on lathes and machining centres, GARANT offers highly productive, dimensionally accurate and process-reliable tools for complete machining.

Since our GARANT broaching process can be used on both lathes and machining centres, all changeover costs are eliminated. Furthermore, additional (cost-intensive) manufacturing processes such as wire-cut EDM (electrical discharge machining) can be dispensed with.

Your benefits at a glance:

- Rapid production of profiles in one work step

- Reduction of set-up costs

- No need to change machines

- No outsourcing needed

Procedure for broaching internal and external profiles

Internal profiles

Preparation of the bore

- To protect the cutting edge and reduce the machining time, select a preliminary bore diameter as large as possible.

- As a guide value for the bore depth t, the following applies for a blind hole: t = desired profile depth × factor 1.5.

- Countersinking the bore makes it easier to centre the broaching tool.

- At larger bore diameters the bore contour remains visible on the faces. This does not impose any technical or qualitative restriction on the functionality of the profile.

External profiles

Preparation of the workpiece

- To protect the cutting edge and reduce the machining time, pre-turn the workpiece to the smallest possible diameter.

- The workpiece diameter must be smaller than the diameter of the circumscribed circle of the hexagonal profile.

- As a guide value for the pre-turned length t, the following applies: t = desired profile length × factor 1.2 bis 1.4.

- A back chamfer or an undercut will allow chips to break cleanly.

- A chamfer on the workpiece facilitates the centring of the cutting insert.

Innenprofile

- Prepare the hole

- Suggest a better translation

- To protect the cutting edge and reduce the processing time, pre-drill the workpiece with the largest possible drilling diameter.

- For a base hole, the following applies as a guide value for the drilling depth t: T = desired profile depth × factor 1.5

- A lowering of the hole facilitates the centering of the broaching insert.

- For larger hole diameters, the hole contour remains easily visible on the surfaces. This has no technical or qualitative restrictions on the functionality of the profile.

Reference values for hole diameter

Außenprofile

Preparation of the workpiece

- To protect the cutting edge and reduce the processing time, pre-rotate the workpiece to the smallest possible diameter

- The workpiece diameter must be smaller than the perimeter diameter of the hexagon profile

- The following applies as a guide value for the pre-turning length t: T = desired profile length × factor 1.2 to 1.4.

- A rear chamfer or undercut promotes chip breakage

- A chamfer on the workpiece facilitates the centering of the cutter insert

Reference values for workpiece diameter

Profile broaching (tumbling) procedure

Create hexagon, square and special profiles in seconds:

- The concentric movement (tumbling) quickly and safely creates the desired profile in just one working step.

- When machining on a CNC lathe, start at a low speed (n ≈ 100 1/min – 200 1/min) and high feed rate (f ≈ 0.1 mm/rev – 0.3 mm/rev).

- After a machining depth of approx. 0.5 mm, set the feed rate and the speed (also see table on page 806 of the brochure).

- Retract at a higher feed rate.

- Cooling lubrication is necessary. Due to the low profile depth, external cooling is sufficient.

If necessary, remaining chips in the base hole can be removed by subsequent drilling (same hole size as for pilot drilling) or by undercutting.

Tip

When machining larger components (such as square 50 mm or hexagon 70 mm), for large width across flats and high-tensile material we recommend the GARANT profile slotting system.

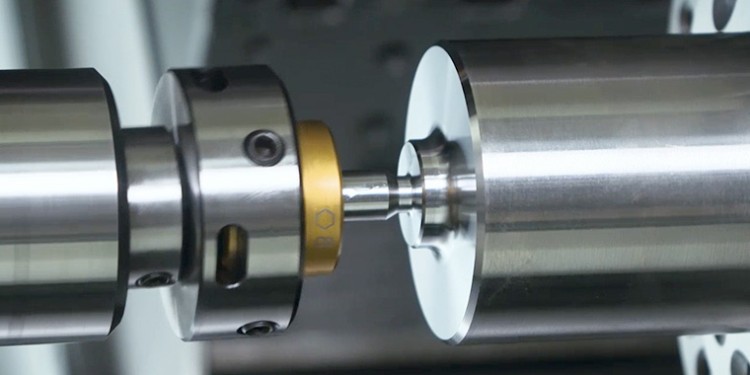

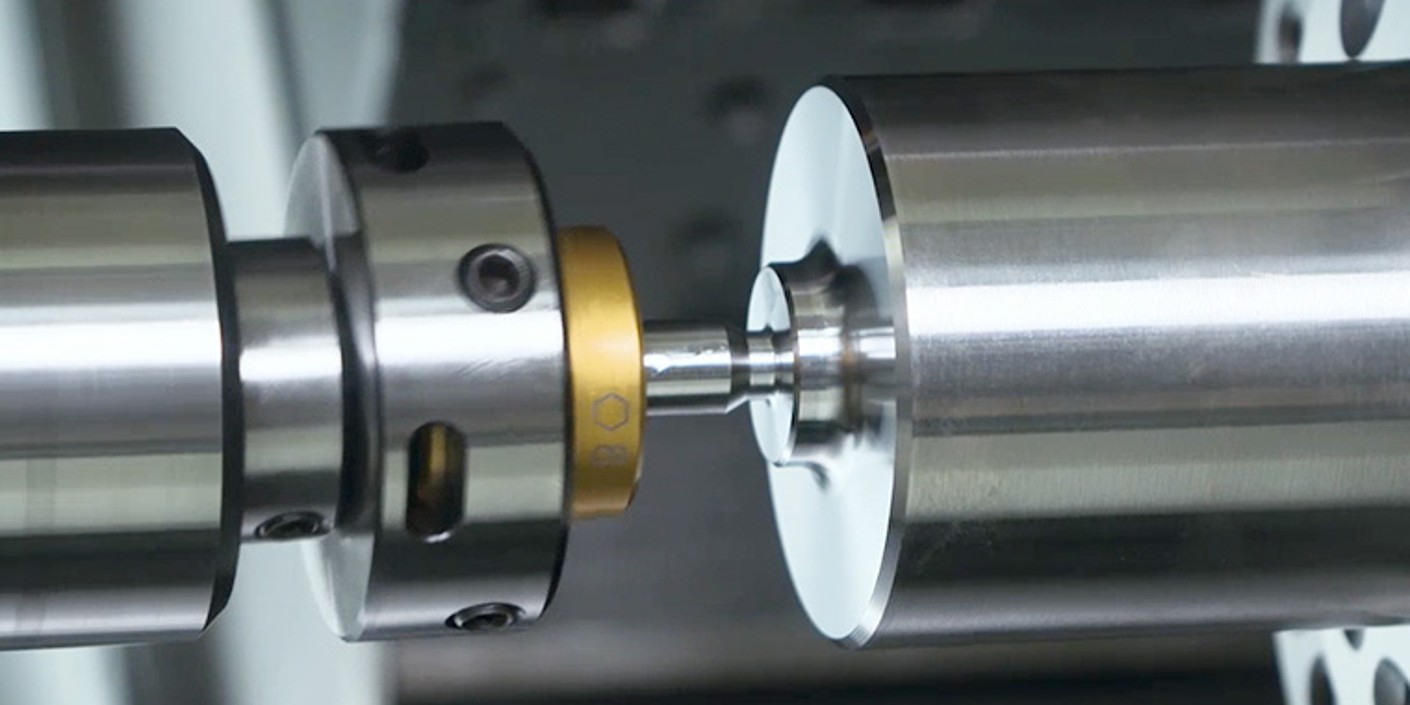

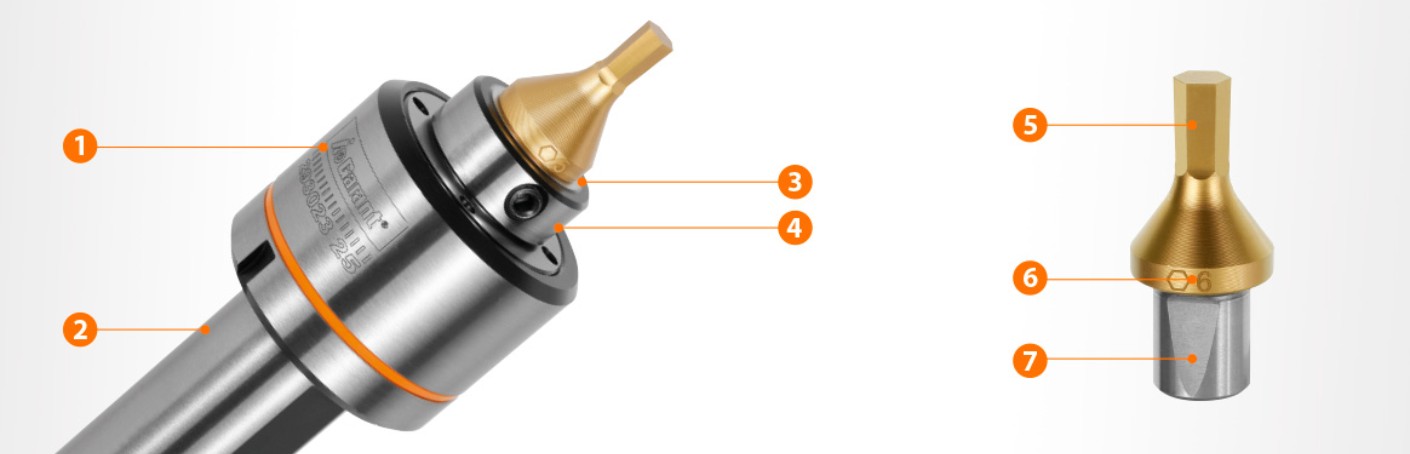

Matching inner profile broaching tool from GARANT

Hexagon, square and Torx® profiles – created in seconds.

- Eccentric design: Suitable for CNC lathes and milling machines and for conventional machines.

- Wide variety of shank connections: Plain, morse taper and VDI shanks. Further connections on request.

- Flat face of the broaching tool holder: Increases the stability and process reliability.

- Hardened and ground: Precision for bearing seats and tumbling headstocks.

- All slotting tools TiN coated as standard.

- Collar on the slotting tool for additional stability.

- Drive flat on the slotting tool for clamping with high process reliability.

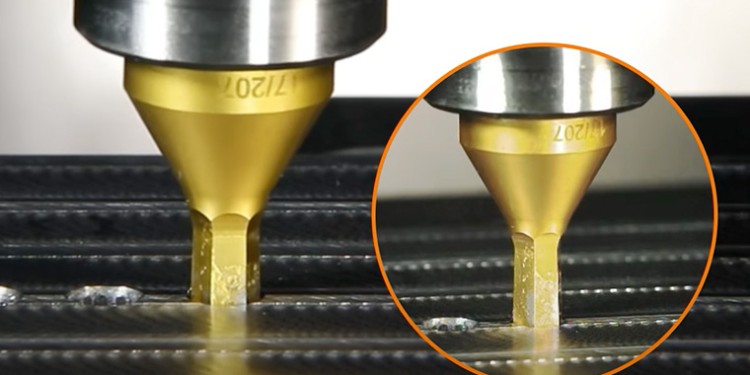

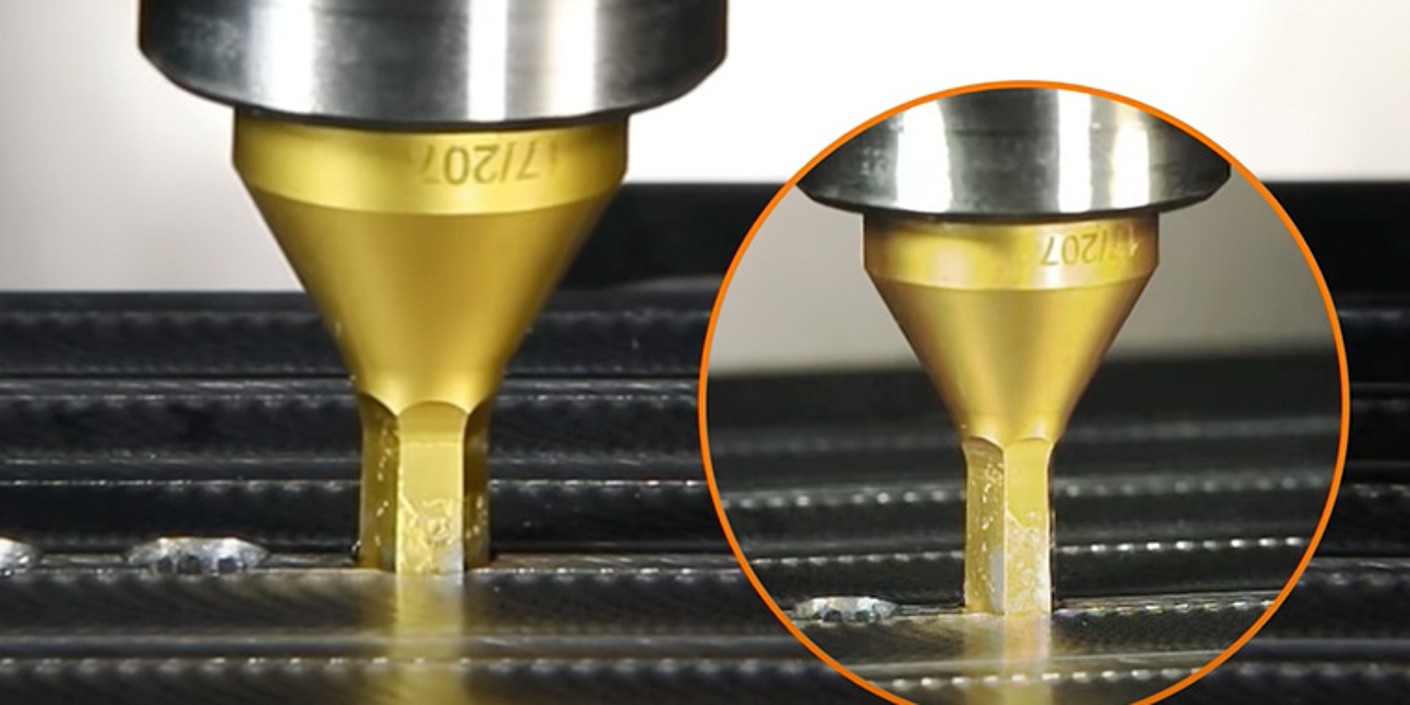

GARANT broaching external profiles

Now get the most out of your lathe or machining centre and produce external profiles in a single pass, with good process reliability.

The benefit to you

- Simple & fast: External profiles are produced in seconds.

- Effective: Maximise your production capacities. No need to switch to another machine, no sub-contracting required.

- Flexible: Special profiles can be produced on request, even at short notice.

With the appropriate toolholders, there is nothing to stop you:

- Toolholders for medium to large batch sizes

- Materials < 900 N

- Medium to large width across flats

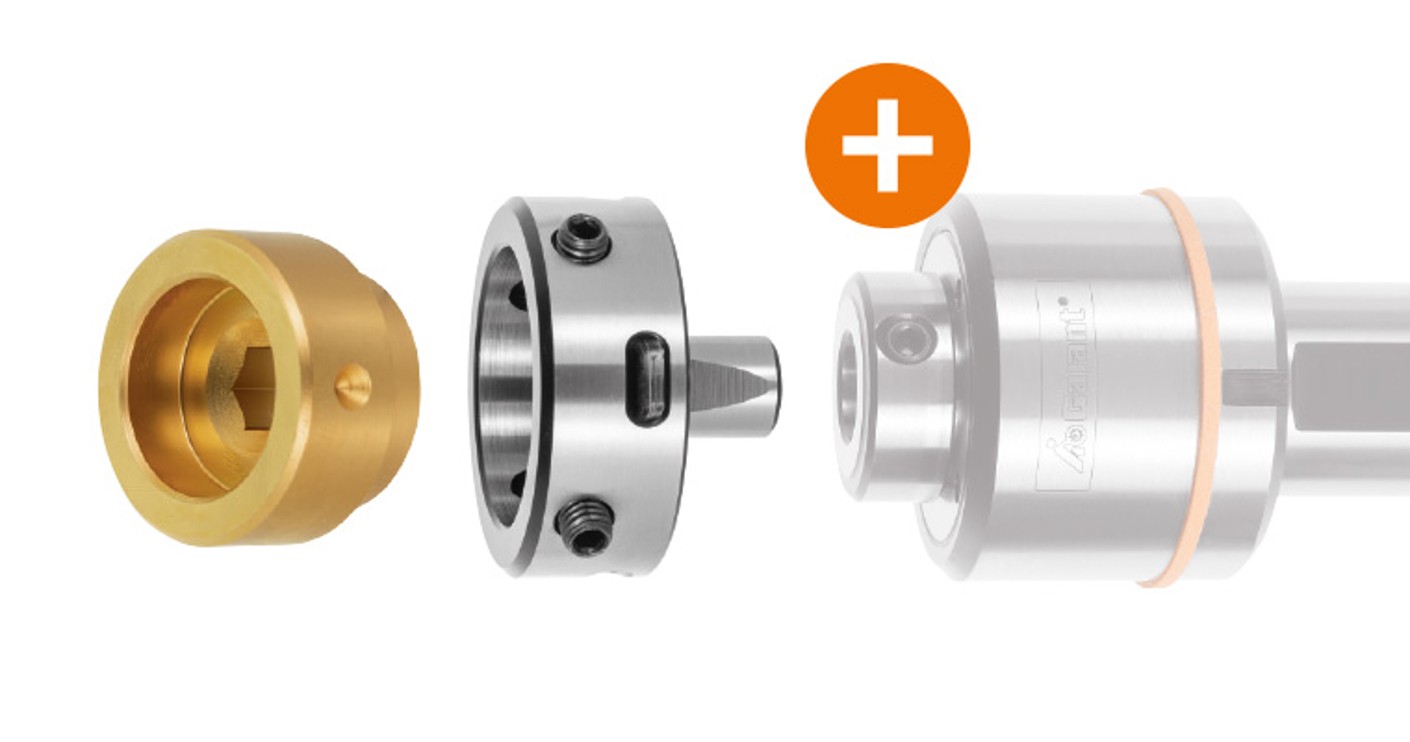

GARANT toolholders for profile broaching with adapters

If you only have an irregular need for external profiles, you can also manufacture these using our adapter solution for internal profile broaching toolholders.

Adapters are your solution for

- only occasional need

- medium batch sizes

- materials y 750 N

- small to medium width across flats

Video GARANT profile broaching

Produce hexagonal, square and Torx® profiles in seconds with the new GARANT profile broaching tools.

The concentric movement (tumbling) quickly and safely creates the desired profile in just one working step.

Your benefits in an overview:

- Rapid production of profiles in one work step.

- Reduction of remodeling costs

- No need to change machine.

- No outsourcing needed.

ToolScout

This is also an opportunity to use the Hoffmann Group ToolScout:

It can be used for tool and cutting data search and provides various programming examples.

To the ToolScout

To the ToolScout