{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

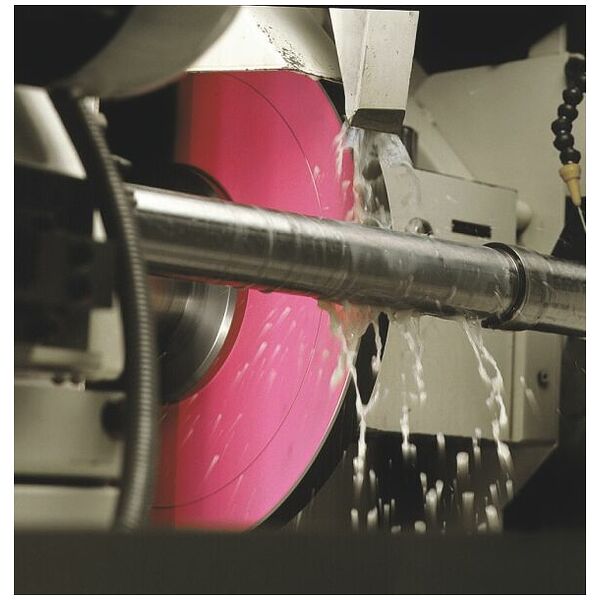

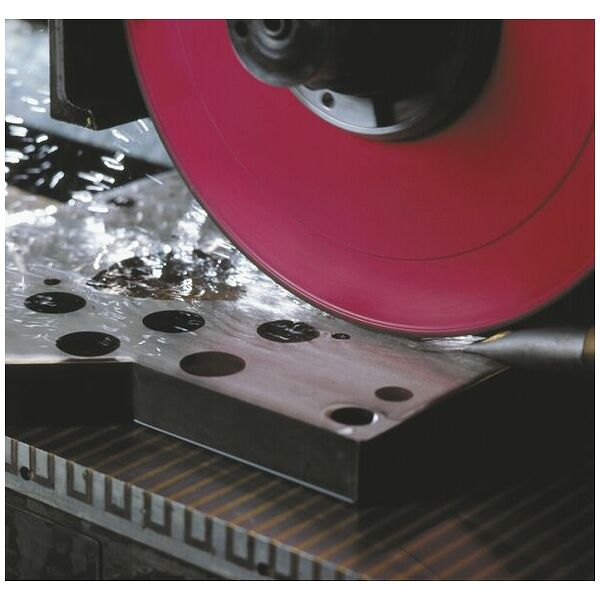

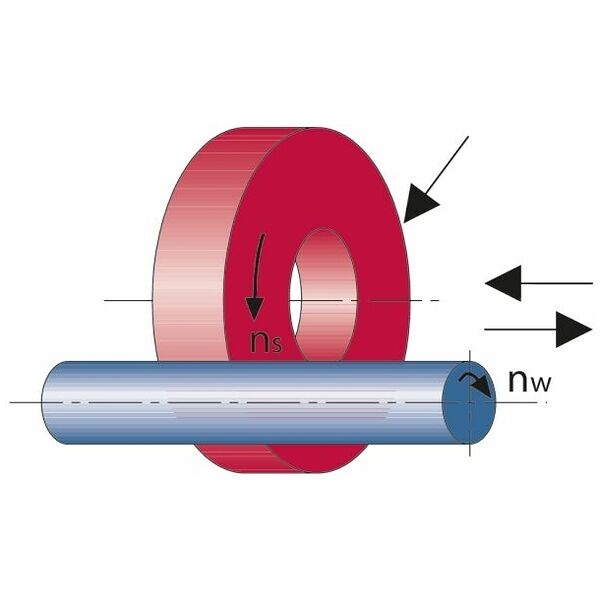

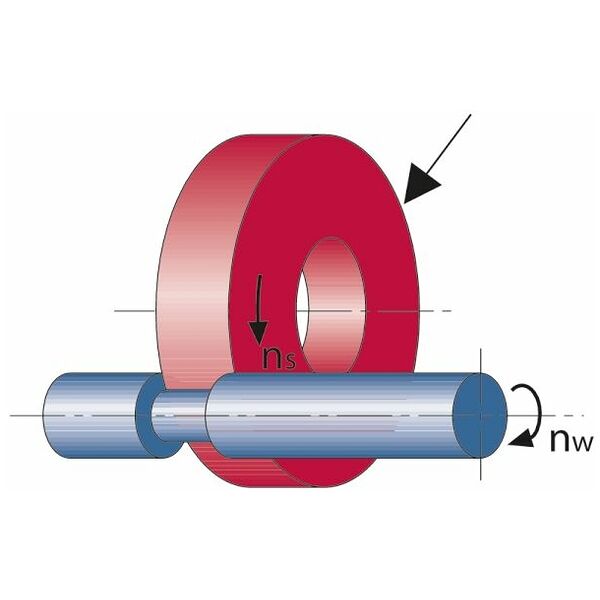

| Grinding process | External cylindrical; Surface grinding | |

| Grinding media | Diamond | |

| Grinding medium code | D | |

| Specification | D126C75B-VIB-STAR W-Carbide | |

| Shape | 1A1 | |

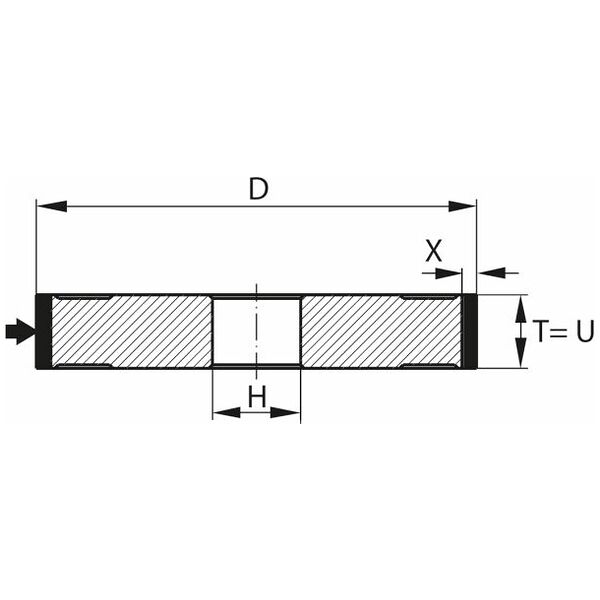

| Disc ⌀ D | 300 mm | |

| Disc thickness T | 20 mm | |

| Bore ⌀ H | 76.2 mm | |

| Abrasive coating width U | 20 mm | |

| Abrasive coating height X | 3 mm | |

| Type of product | Cutting disc |

| Article number |

592050 3

Copy |

|

| EAN / GTIN |

9009012027426

Copy |

|

| Manufacturer number |

34448317

Copy |

|

| Manufacturer/responsible person | Tyrolit Schleifmittelwerke Swarovski KG, Swarovskistraße 33, 6130 SCHWAZ, Austria, www.tyrolit.de |