Version:

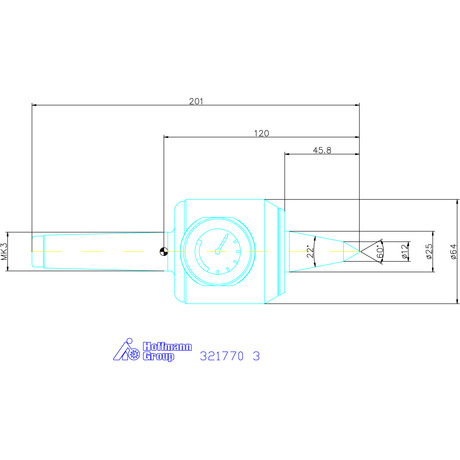

- The adjusting pressure (clamping force) is directly readable on the manometer sight glass in daN.

- The live centre, which is supported by a disc-spring pack, has a long spring travel.

- Short sturdy design with active longitudinal axis. Live centre through hardened and finish ground.

- Maximum accuracy due to precision roller bearings.

- With special seal against dirt and coolant ingress, maintenance-free due to lifetime lubrication.

With extended centre, point angle 60° / 30°.

Description:

Lathe centres are mainly used on lathes to support long and slim workpieces, since with these workpieces there would otherwise be a risk of the workpiece bending or moving around as a result of the forces generated.

The lathe centre is secured with a Morse taper. The workpiece is clamped in the chuck and a counterbore is added using a centre drill. After re-clamping, the lathe centre is then inserted.

Application:

Whenever

the clamping force has to be kept within certain limits,either to prevent deformation of the component or to ensure secure clamping with sufficient pressure.

- As a tailstock centre in conjunction with hydro-mechanical face drivers No. 327451 − 327541 because the drive teeth have to dig into the component.

- For components that expand significantly due to high machining heat.

- For clamping long slender components to prevent lateral displacement.

- For clamping heavy components where a controlled clamping force is required.