{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

| Series | Master Steel | |

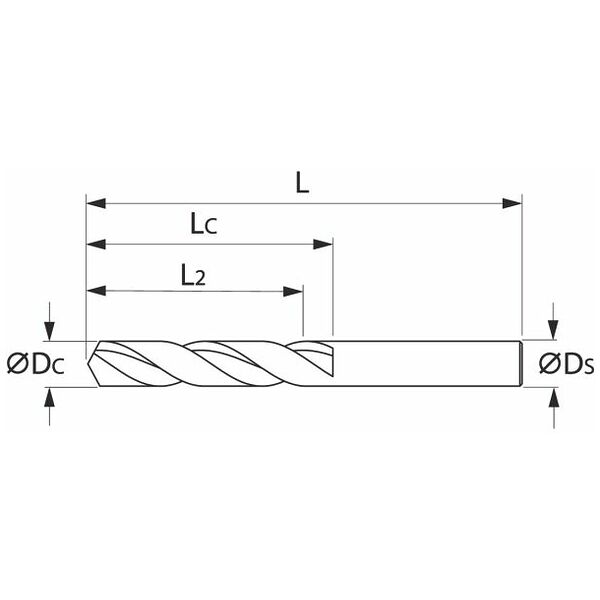

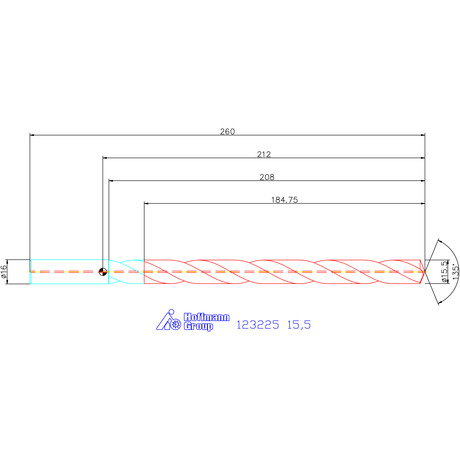

| Nominal ⌀ DC | 15.5 mm | |

| Coating | TiAlN | |

| Tool material | Solid carbide | |

| Standard | Manufacturer’s standard | |

| Version | 12×D | |

| Tolerance nominal ⌀ | h7 | |

| Number of cutting edges Z | 2 | |

| Point angle | 135 degrees | |

| recommended maximum drilling depth L2 | 184.8 mm | |

| Shank | DIN 6535 HA to h6 | |

| Through-coolant | yes, to 25 bar | |

| Machining strategy | HPC | |

| Semi-Standard | yes | |

| Flute length Lc | 208 mm | |

| Overall length L | 260 mm | |

| Shank ⌀ Ds | 16 mm | |

| Feed f in steel < 1100 N/mm2 | 0.26 mm/rev. | |

| Colour ring | green | |

| Type of product | Jobber drill |

| Article number | 123225 15,5 | |

| EAN / GTIN | 4045197845832 | |

| Manufacturer number | 123225 15,5 |