Improved resource planning – use materials efficiently

Often, existing calculations in companies are no longer compatible with the energy and raw materials costs that are rapidly increasing in recent times. Supply problems and bottlenecks also lead to increased operating costs and complications in cost planning. In the following, we will show you how optimising your resource planning step-by-step can help you succeed at your goals of improving operating processes and saving costs.

Sustainability is an essential pillar of any healthy company structure. This now goes far beyond thinking in terms of climate efficiency. For industrial companies, sustainable business also means maintaining stable customer relationships and investing in tools and inventory which retain their high quality in the long term.

Investment in durability and quality

A process is only as good as the materials used in it. Signs of tool wear are noticeable in the fact that processes require more time and effort, more energy input and higher personnel costs, for example. With our products from the GARANT brand, we guarantee especially long-lasting and reliable top quality, and therefore better planning certainty, with a 10 year warranty*.

With GARANT, we guarantee durability

GARANT is our system tool for everything falling within 10 metres of industrial workstations – with reliable high quality. GARANT quality includes:

- 10-year warranty on GARANT products**

- Production at the world’s best production facilities

- Our in-house development team, twelve in-house technology centres and certified test methods

- Excellent price-performance ratio

- More than 55,000 GARANT products from application areas such as machining, clamping technology, hand tools, workstations and storage, personal protective equipment and more

* 10-year warranty on materials and manufacture of GARANT products when used as intended, excluding regular wear as a result of mechanical stress and excluding all electronic components.

** 10-year warranty on materials and manufacture of GARANT workstations and storage products when used as intended, excluding regular wear as a result of mechanical stress and excluding products installed in containers as well as all electronic components.

Focus on resource-saving materials

Bottlenecks for raw materials have become a global problem. Wood, which is especially important for company and factory equipment, also suffers from this. Alternative and renewable materials are becoming more and more attractive. But it’s not just availability that’s important – quality and price also factor into convincing people to make the change. Changing to materials from renewable sources pays off multiple times over. Resources are conserved, waiting times reduced, all while avoiding the rising price level for limited raw materials.

In comparison to wood, bamboo is a very fast regenerating resource. Even though we talk about bamboo as a wood, bamboo is actually a grass. Some types can grow up to a metre a day. Because of this, massive amounts can be harvested every year without endangering its existence. This is because when it is felled, the entire plant does not die – unlike with a tree. Because bamboo is very hard and dense, it is possible to make robust, long-lasting furniture from it which is simultaneously lightweight and highly flexible.

Upgrade or replace workstations and storage at your own pace

Modular workstations and storage lines such as our GARANT GridLine give you greater flexibility in your choice of materials. Individual components can be freely assembled and easily replaced. So, for example, for worktops you can use the fast renewing raw material of bamboo as an alternative to wood.

A workstation is a big investment which should not be taken lightly. Perhaps you would like to set up a new production space at a later date. Or add matching parts to your inventory after a few years? With the 10-year availability guarantee on GARANT GridLine products you can rest assured that every workstation built by us can be reproduced or enhanced with spare parts and accessories.

Learn more about GARANT GridLine here.

When it comes to your inventory, save raw materials without compromising on quality

Whether info point or tool wall – those who value maximum flexibility and easy handling when choosing equipment will find it with GARANT Uni Line. Our modular provision systems in industrial quality are designed so that individual components such as bases, drawers or perforated panels can be combined and replaced very easily. This frees you from costly, static custom builds. At the same time, by choosing GARANT Uni Line you are getting especially high-quality and robust materials which are, for the most part, recyclable by material type. The products are constructed with the lowest possible use of materials, but are still very durable. This not only conserves raw materials but also saves on weight, making transport and installation much easier.

Further information on GARANT Uni Line can be found here.

GARANT Uni Line offers maximum versatility with easy installation and reduced raw material consumption.

Increase the durability of your tools

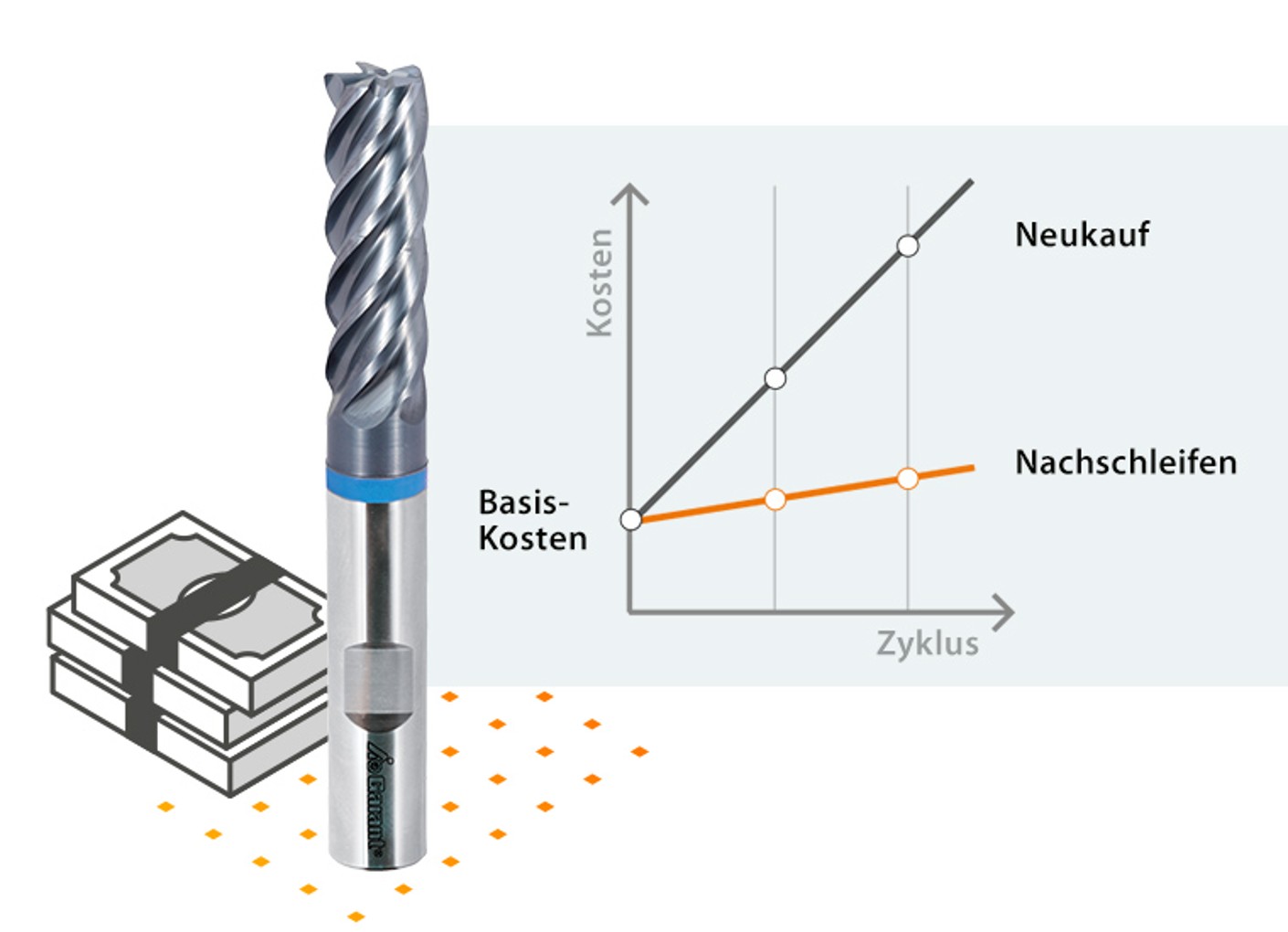

Maintaining what you have is the most obvious approach to resource planning. With everyday use, signs of wear cannot be avoided but they can be significantly delayed. With regular reconditioning, such as with our regrinding service, the service life of your tool can be extended by up to 3-4 life cycles.

The tendency is often still to replace a tool, rather than repair it, despite that being the best choice to save resources. What seems easier at first glance is usually due to unanswered questions. We answer some of the most common ones here:

When is regrinding worth it?

When you send your tools for regrinding in a timely manner and pay attention to high-quality regrinding. To prevent wear from progressing in the first place, check your tool regularly to see if it could use regrinding. Tip: it is best put an appointment in your calendar as a reminder.

Which tools can be reground?

Most tools can be reground. The more complex the geometry, the more expertise is required. Only a few tools cannot be reground. We are happy to help you and advise you on our regrinding service.

How do you know when regrinding is necessary?

There are some visual indications, such as burr formation, declining surface quality of the workpiece that was machined by the tool or a deformed profile. You will also notice it during use, for example due to higher forces on the machine, a change in milling noise or the tool causing louder noises.

Quality when it comes to personal protective equipment increases wearer acceptance

Above all when it comes to the personal protective equipment of your employees, making an investment in high-quality and long-lasting products pays off. Here, disposable products are widespread, especially for hearing protection. However, it is precisely here that a high level of comfort during use and high effectiveness are important. Earplugs which do not provide an optimum fit are thrown away sooner or not even used at all.

According to statistics, 84% of employees in industrial companies still do not use hearing protection reliably, despite exposure to noise. Also, the effectiveness of disposable hearing protection is only 31% according to a study by the INRS (Institut National de Recherche et de Sécurité).

Good resource planning also makes a difference here: changing to individually adapted hearing protection, so-called otoplastics, leads to the employees being optimally protected from noise-related health risks and it achieves very high acceptance amongst wearers. This is good for the environment because much less waste is produced and valuable raw materials can be saved. Adapted hearing protection also has definite economic advantages: it offers a savings potential of up to 67% in a year compared to disposable hearing protection. Per pair of adapted hearing protectors, based on a warranty period of six years, there is a savings potential of over 38 euros a year.

Learn more about hearing protection here.

Products with special sustainability requirements

Sustainably produced products are generally especially carefully checked during development and comply with modern technological standards. You can buy products from us with the new “Uvex Protecting Planet” label – these are classified as being particularly sustainable. They guarantee that the entire process can be followed, from development to sale. Products from the Uvex brand are made, as much as possible, from bio-based or recycled materials. With the 3-in-1 safety glasses range Uvex i-range Planet, the sustainable raw material that is the castor plant makes up 38% of the material of the frames, for example. The uvex Bamboo TwinFlex® cut-resistant glove is made out of 45% bamboo viscose and recycled polyamide.

The upper material of the Uvex safety shoes 1 G2 planet is completely made out of recycled PET bottles.

Conclusion: resource planning is a continuous process

Even small adjustments for a more efficient use of resources make themselves felt in the long term. Therefore it is worth regularly taking stock of where you can save resources and reduce costs:

- Where can you extend the working life of your existing tools?

- When does it make sense to purchase a new tool – for example to reduce power consumption or to improve performance capability?

- Where can resources be saved by switching to sustainable products and materials?

The Hoffmann Group team are happy to advise you here.