Safety signs and floor markings

Instructions on conduct for employees and visitors in order to prevent accidents

Not all areas in the production halls are accessible to everyone. Only trained personnel should operate machinery and escape routes should be quickly and clearly recognisable for everyone present. To meet these requirements using a clearly visible solution, safety signs are very helpful and indeed legally required. Safety signs must be used at the workplace in order to protect the employees and prevent accidents. The safety signs to be used are specified in the European standard EN ISO 7010 and, in Germany, in the Technical Rules for Workplaces (also known as workplace rules or ASR for short) section A1.3 (signs for safety and health protection). The signs must be permanently attached and clearly visible in all companies and public buildings and in places where personnel need to be protected. This should be taken into account when planning new workplaces. In our wide range of safety signs you will find mandatory signs, prohibition signs, rescue signs, warning signs and fire safety signs.

Information about safety symbols and safety signs

Colour and shape of safety signs

To ensure that safety signs are clearly recognisable, their colours have been given standardised definitions in ISO 3864-4. The colours designated in columns 3, 4 and 5 (see table below) must also correspond to the specifications of ISO 3864-4. The contrast colour also includes luminescent pigments.

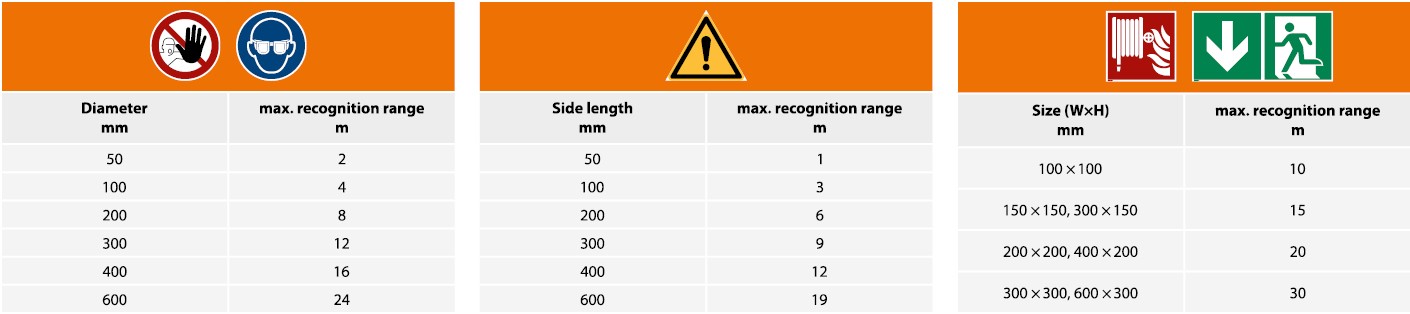

Suitable size for safety signs and their legibility distance

The size selected is key to determining from how far away the sign can be recognised. The further away the sign must be recognised, the larger the safety sign should be. There are differences between the respective types of signs (see table below).

Example: The prohibition sign “No unauthorised access” is selected with a diameter of 100 mm. As such, the sign will be clearly visible from a distance of 4 m. However, if this distance is too small, the diameter will need to be increased.

Safety signs with long-lasting luminescence

Fire safety and rescue signs with long-lasting luminescence are used if there is no safety lighting or if the general lighting fails. Our luminescent products far exceed the minimum values stipulated in DIN 67510. The following factors affect luminescence:

- Intensity of charging light

- Illumination type

- Illumination period

- Sign pigments

In the age of LED lighting, the light colour is crucial. Cold white has the intensity with the highest charge.

Selection criteria for a safety sign: materials science

In practice, there are many ways to indicate potential dangers at the workplace. Choosing the right material is essential to ensure longevity and prevent a safety sign from becoming damaged. The material should be selected to suit the location where the safety sign is being used. Four materials with different properties are available. This information will help you choose the right sign for your needs.

Custom safety signs and stickers

Hoffmann Group can produce various fire safety and rescue signs with your company logo or custom text on them. You can design stickers and signs for indoor and outdoor use in your desired colours and with your logo. Custom parking signs and added text in any language are also available. Check here to see what details we need from you in order to make your custom designs.

The benefits for you:

- Compliance with employee protection measures

- Lower accident rate, thereby reducing the cost factor

- Ensuring employees’ general understanding

- Top quality to protect employees and others

- Comprehensive range – reliable supply

- Targeted consultation by our PPE specialists.

Norms and standards

The introduction of the new occupational safety signs as per ISO 7010 and, in Germany, as per ASR A1.3 (2013) has resulted in major changes at workplaces. In Germany, ASR A1.3 replaces key parts of the older trade association regulation governing occupational health and safety (BGV A8 – accident prevention).

The use of the current safety signs to ASR 1.3 (2013) is required by the legally enforceable Factories Acts. If obsolete safety signs (as per ASR 1.3 (2007) or BGV A8) are used, a risk assessment must be performed by the company to check that the safety signs can be relied on to ensure protection of employees. Refer to this to check whether changing obsolete safety signs is recommended.

ISO 7010

- International standard specified by the European Committee.

- International standard adopted in Europe and also Germany (DIN EN ISO 7010).

- Uniform definition of safety signs applicable across a number of European countries.

ASR A1.3

- Technical rules for workplaces (safety and health protection signs).

- Supersedes the old regulations as per BGV A8.

- Adoption of the safety signs specified in ISO 7010.

- By applying these regulations, employers satisfy their obligations to provide safe workplace signage.

BGV A8

- German trade association regulations for health and safety at work.

- Regulation of health protection and occupational safety signs.

- Currently only valid in sub-areas.

- Important points are now covered by ASR A1.3.

- Use of safety signs as per BGV A8 only permissible in conjunction with a risk assessment.

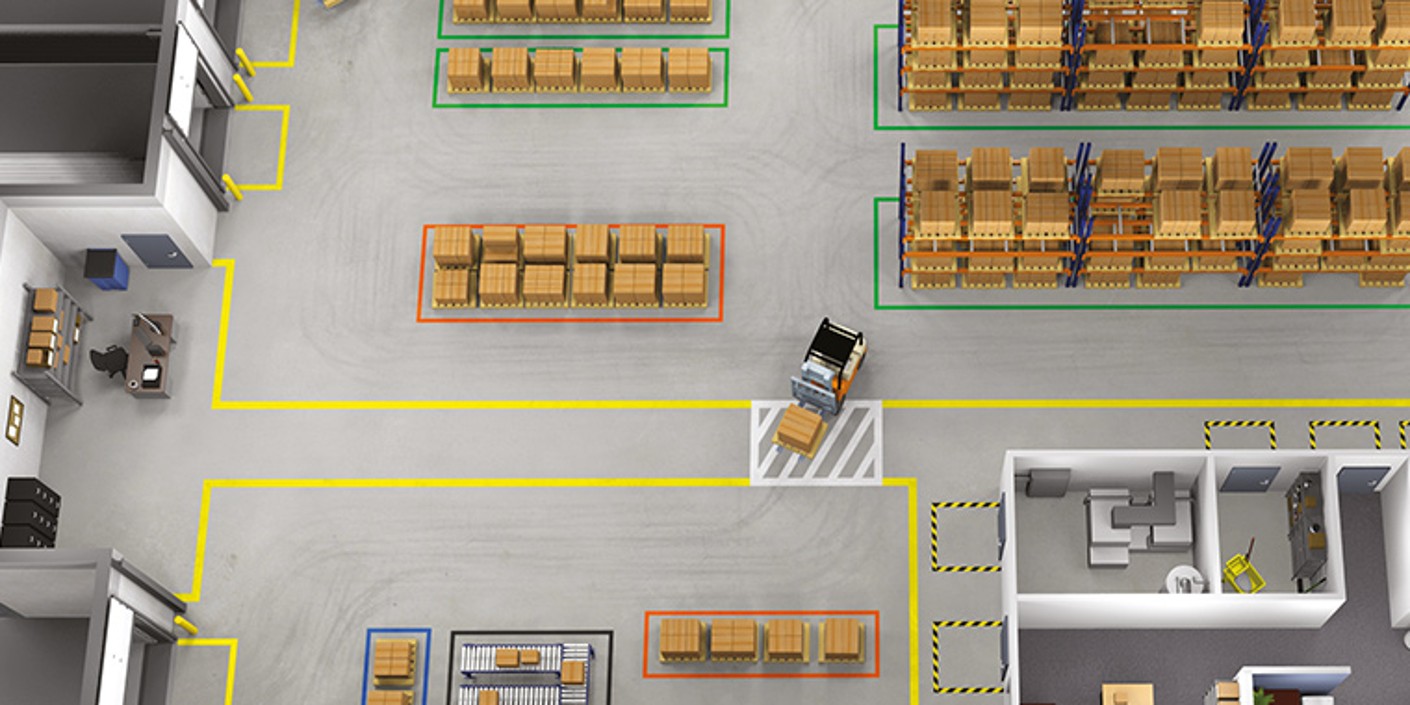

Floor markings and safety markings

Adhesive tapes for safety markings combine flexibility, durability and efficiency. To apply new markings you do not need to sand the old ones off, then re-apply and cover them and wait for them to dry – a time-consuming process overall. This means you don’t waste time or money and you do not have to make any compromises.

Flexibility

Do you need to adapt your working environment to ongoing changes? Adhesive tapes can be attached and removed quickly and efficiently. As such, they can help you to adapt your working environment equally quickly and efficiently.

Longevity

Adhesive tapes are available for a very wide range of applications. We offer tough adhesive tapes that meet your stringent requirements.

Efficiency

Worn markings often have to be repainted, which can lead to long downtimes. The use of adhesive tapes can significantly speed up this process.

Instructions for applying floor marking tapes

- Before application, the floor must be clean and dry.

- Clean the floor with isopropyl alcohol and allow it to dry for 30–60 minutes.

- Optimum adhesion at an application temperature between 15° and 20°C.

- Perform an adhesion test using a small piece of adhesive tape.

- Press the adhesive tape on using a squeegee or roller, taking care to apply sufficient contact pressure.

- Form corners by means of a diagonal cut or butt joint.

- The adhesive tape can be walked on after 10 minutes, driven over by fork-lift trucks after 24 – 48 hours.

- Do not turn, steer or brake fork-lifts on the adhesive tape.

To receive advice

To receive advice