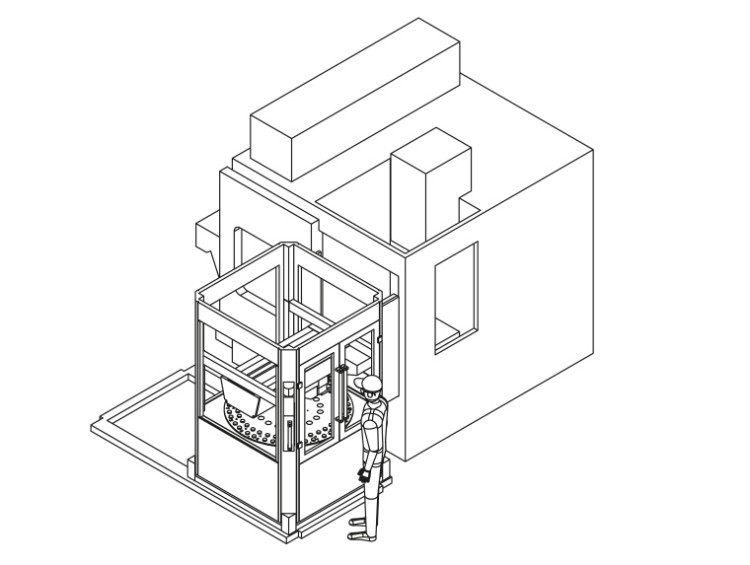

GARANT Automation Turntable loading system: automated clamping device loading system

The GARANT Automation Turntable loading system is probably the most space-saving and easiest way to automate your machine tool. With our clamping device loading system, you can increase your output immediately. You can operate additional shifts in your production and still reduce the workload for your employees.

6 advantages of the GARANT Automation Turntable loading system

No automation interface required

- No automatic door required

- No robot programming knowledge required

- Existing and new machines can be automated

- Can be integrated within a few days (quick start to production)

- One contact person for all matters (automation, machining process, workstation etc.)

- Coordinated clamping device

Highlights of the GARANT Turntable

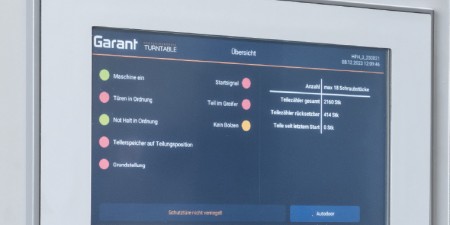

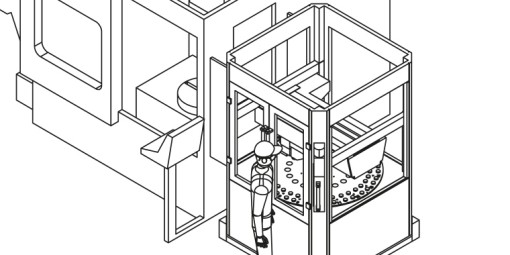

The system is very easy to use

No programming knowledge required thanks to mechanical start/stop bolt system.

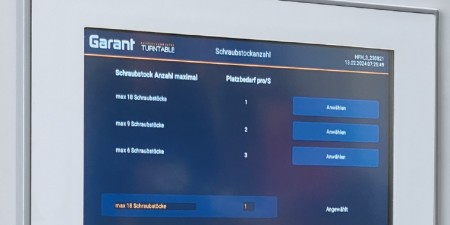

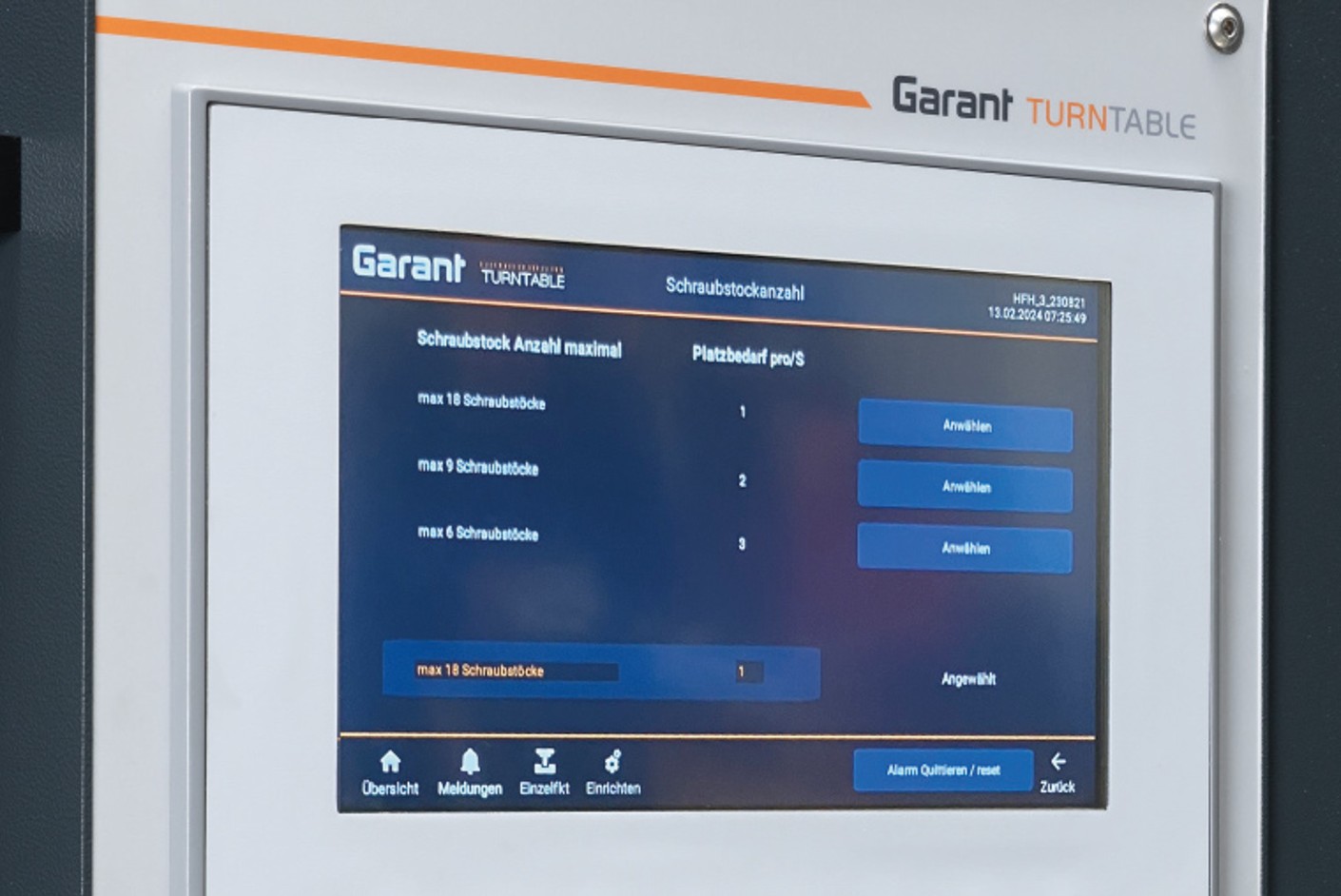

3 different configuration modes for maximum component variance.

Wide selection when choosing clamping devices – from the vice and fixtures to the pallet solution.

Clamping device handling of up to 25 kg

Max. 300 × 190 × 247 mm (L × W × H), incl. clamping device

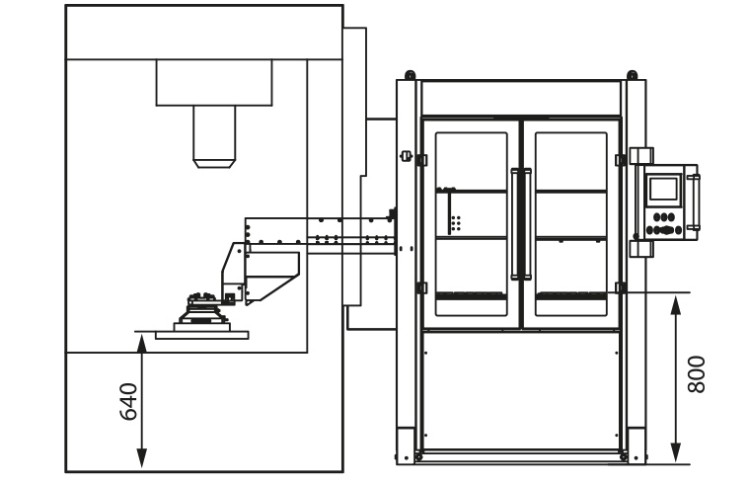

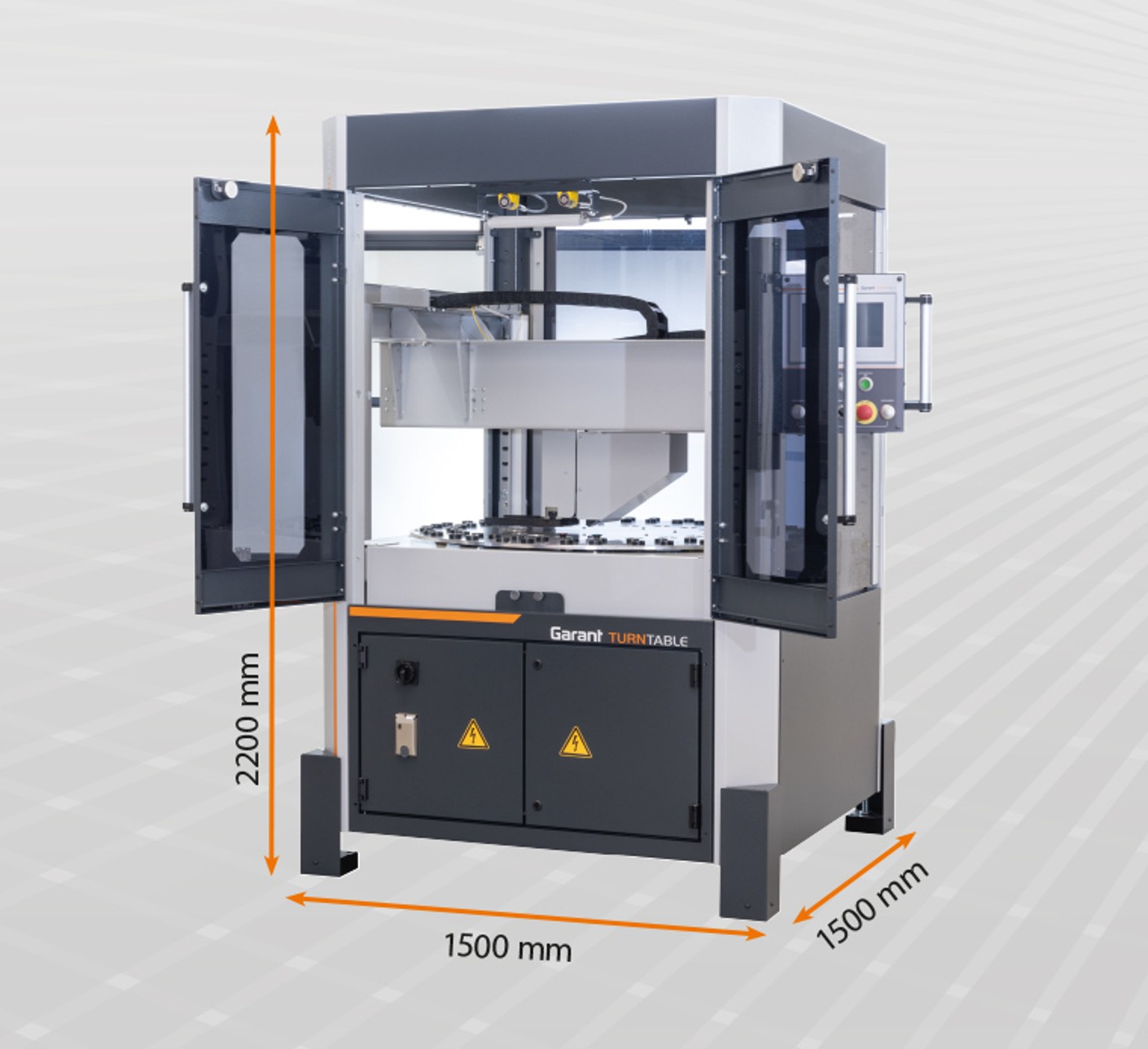

Space required < 2.5 m²

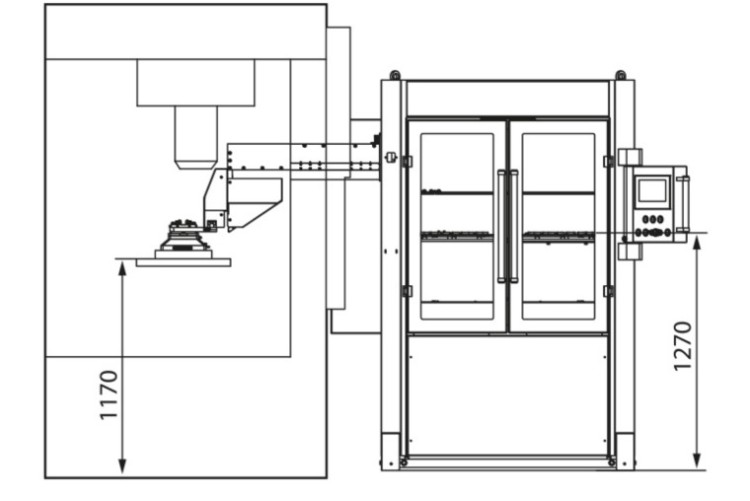

1500 × 1500 × 2200 mm (L × B × H, mounting dimensions)

Extremely simple machine connection

No automation interface necessary

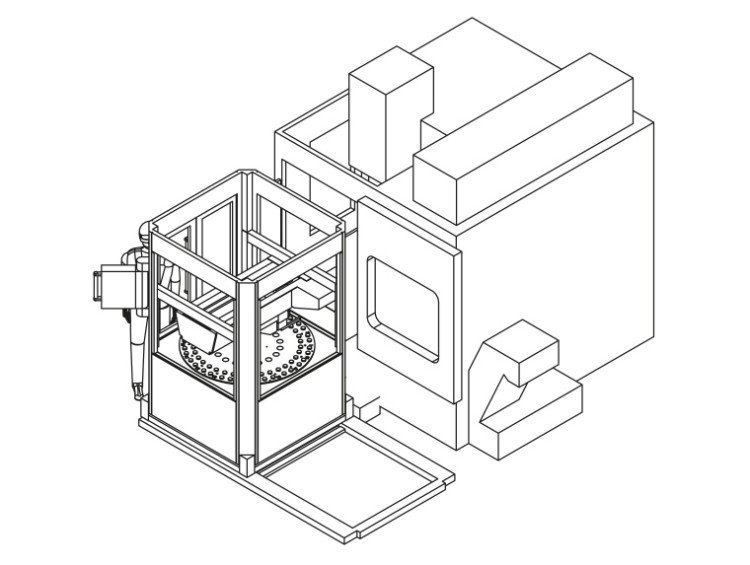

Extremely different variants

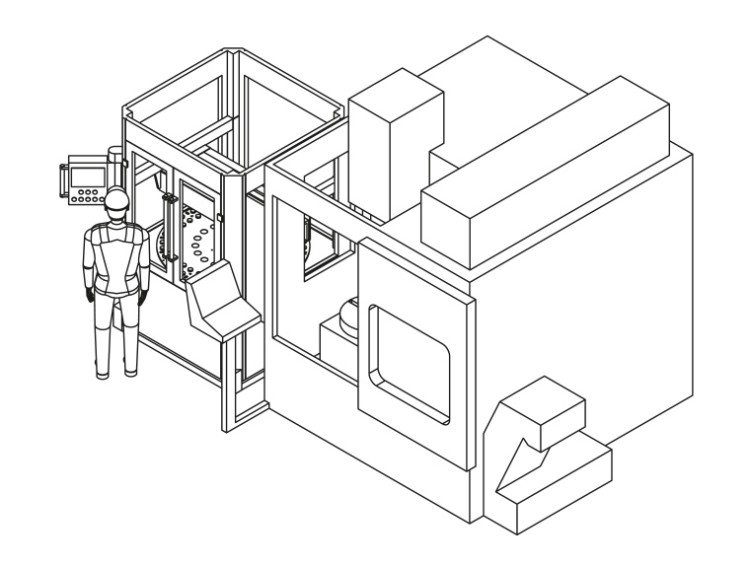

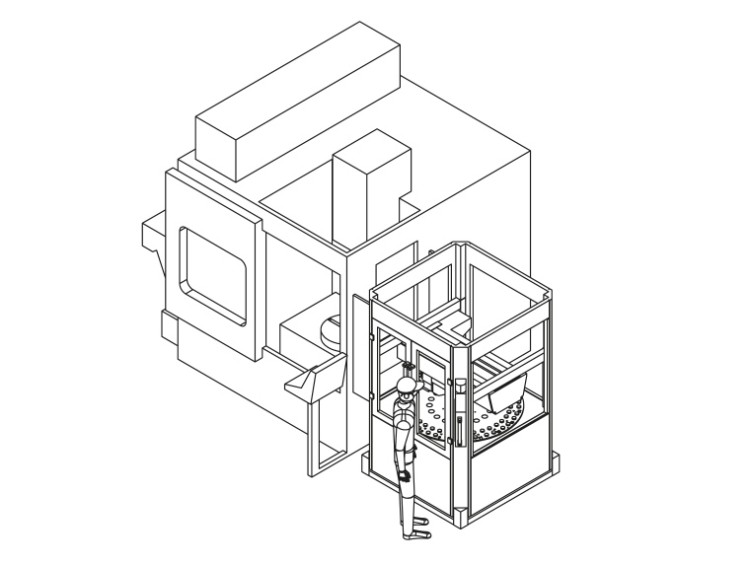

Left-hand and right-hand version for front or side loading and unloading

Loading window with side installation

Sliding unit with front installation

Overview of technical data

Compressed air supply

Quick-release couplings nominal value 7.2 min. 6 bar

Interfaces

Voltage / phases / frequency: 400 V / 3 / 50 Hz

Current at full power / SCCR: 16 A / 10 KA

Power: 5.07 kVA

Dimensions

1500 × 1500 × 2200 mm (W × D × H)

Transport weight

1200 kg

Transport fork length

Minimum 1500 mm

Available to order now: the GARANT Turntable with up to 24 loading bays

| GARANT Turntable 18 | GARANT Turntable 24 | |

|---|---|---|

| 18 Loading bays | Storage capacity | 24 Loading bays |

| 25 kg | Max. handling weight (incl. clamping device) | 20 kg |

| 80 mm | Stitch dimension clamping device | 52 mm |

Ca. 125 x 200 x 247 [mm] Ca. 300 x 190 x 247 [mm] Ca. 440 x 150 x 247 [mm] | Max. clamping device dimensions incl. workpieces 18 // Loading modes // 24 9 // Loading modes // 12 6 // Loading modes // 8 | Ca. 80 x 145 x 247 [mm] Ca. 245 x 145 x 247 [mm] Ca. 475 x 110 x 247 [mm] |

Set up in parallel to the main time

Do you want to get the most out of your machine tool? Then simply set up in parallel to the main time and earn money while you are still setting up. Our GARANT Turntable makes this possible.

Turntable how-to in 6 steps: Unleash the potential of your machine tools.

Automated clamping device loading system made easy: Your new expert for clamping device handling

Planning made easy: Installation as required

The GARANT Turntable adapts perfectly to the conditions in your production. Our automation solution can be planned in a wide range of ways. For your specific needs.

Installation plan A

Left automation with loading window

Installation plan B

Right automation with loading window

Installation plan C

Front automation with sliding unit to the left

Installation plan D

Front automation with sliding unit to the right

Installation plan E

Front automation with sliding unit perpendicular to the machine

Installation plan F

Front automation without sliding unit

Just take a step into the future – with us at your side

The sophisticated design of the GARANT Turntable makes planning and installation simple and easy. Since there is no need to intervene in the control software, the system can also be installed on your machine tool without major adjustments. Our consultants are there for you at every step – and make the process as simple as possible for you. From consultation to training.

1. Advice on site

2. Feasibility check

3. Offer

4. Planning and release

5. Integration

6. Commissioning

The GARANT Automation Turntable loading system offers comprehensive accessories

- GARANT Xtouch

- GARANT Xconnect

- GARANT Xcontrol

- GARANT cleaning stick

- GARANT disc brushes

- GARANT GMT 35 vibratory finishing machine

- Ultrasonic cleaning units

- GARANT HCT family

- Industrial measurement technology from RENISHAW

- Connected Manufacturing

Four success stories – our customers are delighted with GARANT Turntable

Four companies tell us their experiences with the GARANT Turntable – and how it makes their lives easier.

“It is perfect for us, as for us it is compact, easy to use and offers more capacity with the same working performance.”

FEMATEC

Size: 8 employees

Production: Steel, stainless steel, non-ferrous metal or plastic components of almost any size

Why have you decided to automate?

A shortage of skilled workers. We have automated so that we can simply scale capacities according to the order situation.

Which machines have been automated?

Heller HF 3500 DL horizontal machine, without automation interface, front loading

Why did you decide to choose the GARANT Turntable?

It is the perfect solution for Fematec, as the level of investment and space required are low and the machine runtime could be ramped up very quickly.

“Small, compact and easy to use – it’s simply amazing that automated loading is so easy.”

ISH HUTTER

Size: 6 employees

Production: Small-scale series and recurring series with batch sizes of up to 10,000 pieces

Why have you decided to automate?

A shortage of skilled workers. Moving from 2 to 3-shift operation without additional staff expenses – we are therefore automating in order to be able to produce larger orders efficiently.

Which machines have been automated?

Two DMU75 monoBLOCK without automation interface

Why did you decide to choose the GARANT Turntable?

It’s small, requires barely any space, is for 18 vices and can be operated by anyone. We now use the GARANT Turntable for batch sizes of three parts and upwards.

“The machine and operation are totally straightforward – this is the big USP.”

SW AUTOMATISIERUNG

Size: 75 employees

Production: Components made from aluminium for in-house special machine production

Why have you decided to automate?

Automation is our core business and we therefore know what potential it offers.

Which machines have been automated?

DMG Mori, without automation interface, side loading

Why did you decide to choose the GARANT Turntable?

We were really impressed by its simplicity, as the system runs unbelievably steadily and reliably. We have increased our capacity by almost 80 percent.

“Crazy – the machine runs almost the whole time it is switched on.”

FK PRÄZISIONSTECHNIK

Size: 20 employees

Production: Prototype manufacturer with series production

Why have you decided to automate?

We increased our capacity thanks to automation and are now able to offer series production. We now produce 100,000 series components per year.

Which machines have been automated?

The 3rd generation of DMU 50, connection via automation interface, side loading

Why did you decide to choose the GARANT Turntable?

The system meets our requirements in terms of vice handling for 2-face machining and is easy to use – you simply have to switch on, start and get running.

Get free consultation

Get free consultation