Semi-automated production with optimised processes

We give you advice on a comprehensive solution

Our consultants use their professional know-how to analyse your processes and find customised solutions for automated production. This means that you benefit from our expertise in rapid changeover and the right clamping technology, as well as from our knowledge of machining and reduced non-productive times. This guarantees you work more efficiently and with greater process reliability!

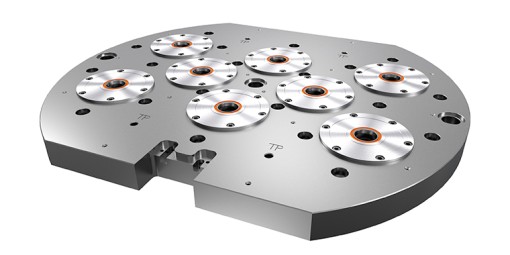

Precise clamping, quick changeover – your key to success with GARANT ZeroClamp

The innovative GARANT ZeroClamp zero-point clamping system is perfectly suited for automation and offers state-of-the-art clamping technology in all situations. For precise clamping and more variability.

One basic unit – outstanding flexibility:

- GARANT Xpent 5-axis vice

- GARANT ZeroClamp base plate

- Pneumatic centring vice

- GARANT ZeroClamp console

- GARANT magnetic clamping plate

- GARANT centring vice

- GARANT HiPo NC high-pressure vice

- ALLMATIC vices

- GARANT 3-way extension base for centring vice

- GARANT flexible clamp

- WITTE vacuum clamping technology

- GARANT multi-point clamping rails 80 and 120

GARANT ZeroClamp offers key benefits for automation:

Reproducibility in seconds

During the day, you can produce prototypes or complicated orders with your specialist personnel. Use the GARANT zero-point clamping system for quick and easy changeover to automatic operation.

Automated loading and unloading

After just a few minutes, you can switch to automatic mode. This eliminates the need to measure components or move to zero points. In combination with a pneumatic vice (e.g. GARANT pneumatic centring vice),

theGARANT Automation Basic loading systemcontrols the opening and closing of the vice jaws.

Save time

Enormous time savings due to lower set-up, changeover and non-productive times.

+ Increase productivity

Less set-up time, more machine runtime

= Increase competitiveness

Process monitoring: the GARANT X trio for greater security

Simple. Attractively priced. Secure.

The GARANT Xtouch is the checker, the GARANT Xcontrol is the security and the GARANT Xconnect brings everything together: Thanks to this dynamic trio, the programmed tool and workpiece measurement and monitoring in automated production is a piece of cake! With wireless transmission, there is no need to adjust anything on the machine control unit.

The benefits to you:

- Easily automate existing machines

- Operation of multiple machines

- Digital zero-point determination = fewer errors

- Conservation of resources: fewer rejects due to tool failure

- Reduces man hours at your machine

The most important features:

- Cycle-controlled measurement transfer

- Retrofitting of existing machine

- Inexpensive automation solution

The advantages our know-how offers to you.

We support you and the automation of your processes from start to finish. No matter whether it’s the storage or provision of tools, work planning or clamping of tools or workpieces, our consultants are by your side and will be sure to find the right solution – depending on the material and work task. We are more than happy to provide advice.

Get free consultation

Get free consultation