Producing perfect profiles

Always the right system for economic production of profiles.

With the overall range for slotting and broaching of profiles on lathes and machining centres, GARANT offers highly productive tailor-made tools for complete machining with high process reliability. Depending on the application, there are two different tooling systems available for economic production of profiles.

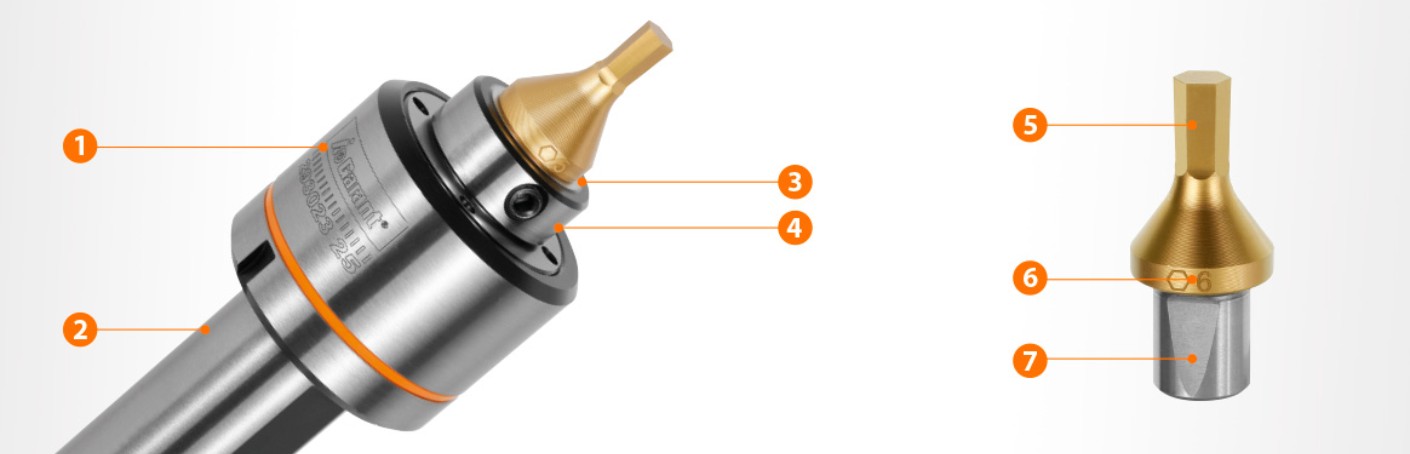

GARANT profile broaching

Hexagon, square and Torx® profiles – created in seconds.

- Eccentric design: Suitable for CNC lathes and milling machines and for conventional machines.

- Wide variety of shank connections: Plain, morse taper and VDI shanks. Further connections on request.

- Flat face of the broaching tool holder: Increases the stability and process reliability.

- Hardened and ground: Precision for bearing seats and tumbling headstocks.

- All slotting tools TiN coated as standard.

- Collar on the slotting tool for additional stability.

- Drive flat on the slotting tool for clamping with high process reliability.

This is how to do it

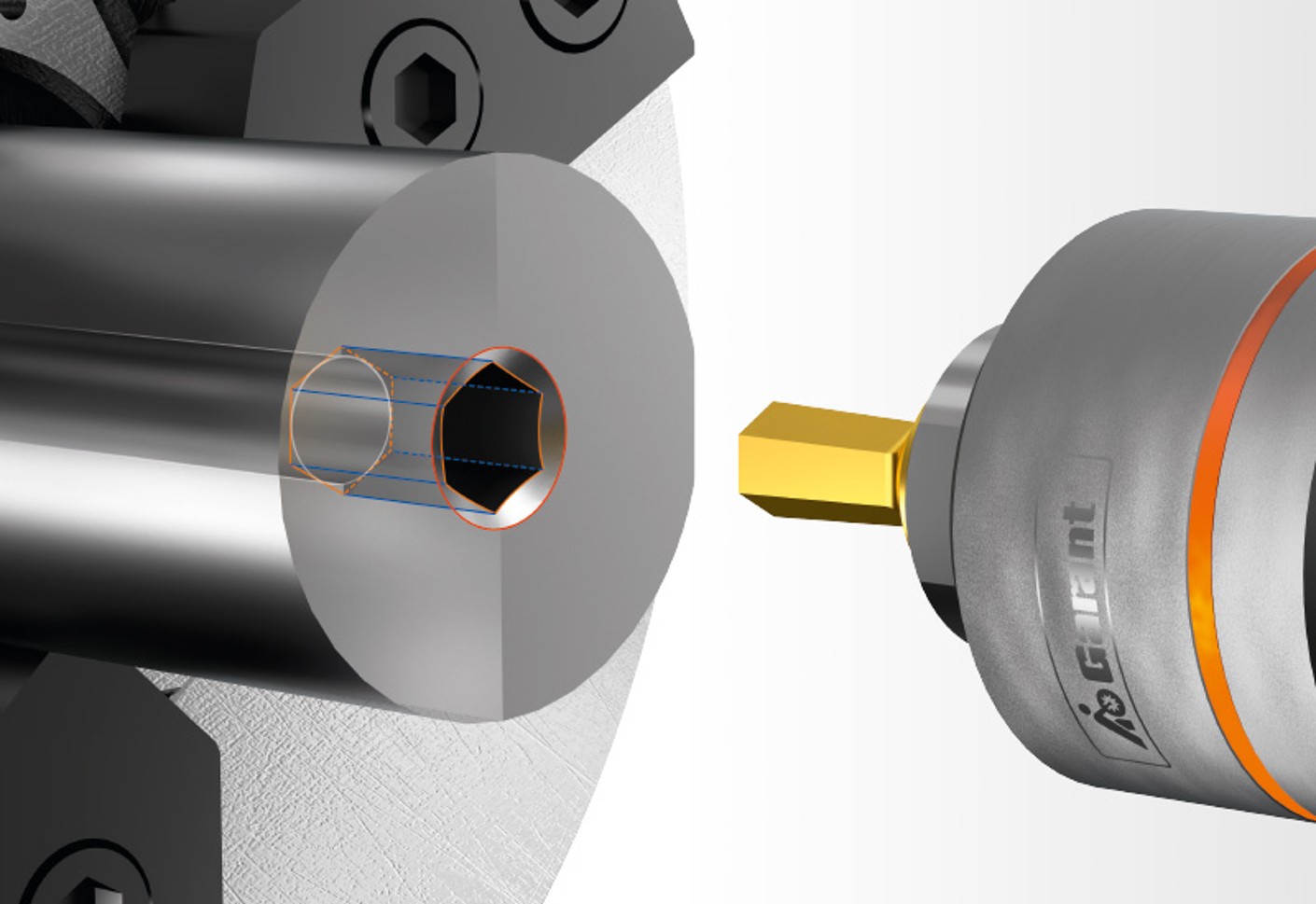

Step 1 Preparation of the bore

To protect the cutting edge and reduce the machining time, select a preliminary bore diameter as large as possible. At larger bore diameters the bore contour remains visible on the faces. This does not impose any technical or qualitative restriction on the functionality of the profile.

Step 2 Profile broaching (tumbling)

When machining on a CNC lathe, start at a low speed (n approx. 100 rpm – 200 rpm) and high feed rate (f approx. 0.1 – 0.3 mm/rev). After a machining depth of approx. 0.5 mm, increase the feed rate and speed as shown in the table (see the product page for slotting tool). Retract at high feed rate.

Cooling lubricant is necessary. If the profile depth is small, external cooling is sufficient.

Step 3 Finish machining

Chips remaining in the blind hole can be removed if necessary by drilling out (the same diameter as the pre-drilled hole) or by relief groove.

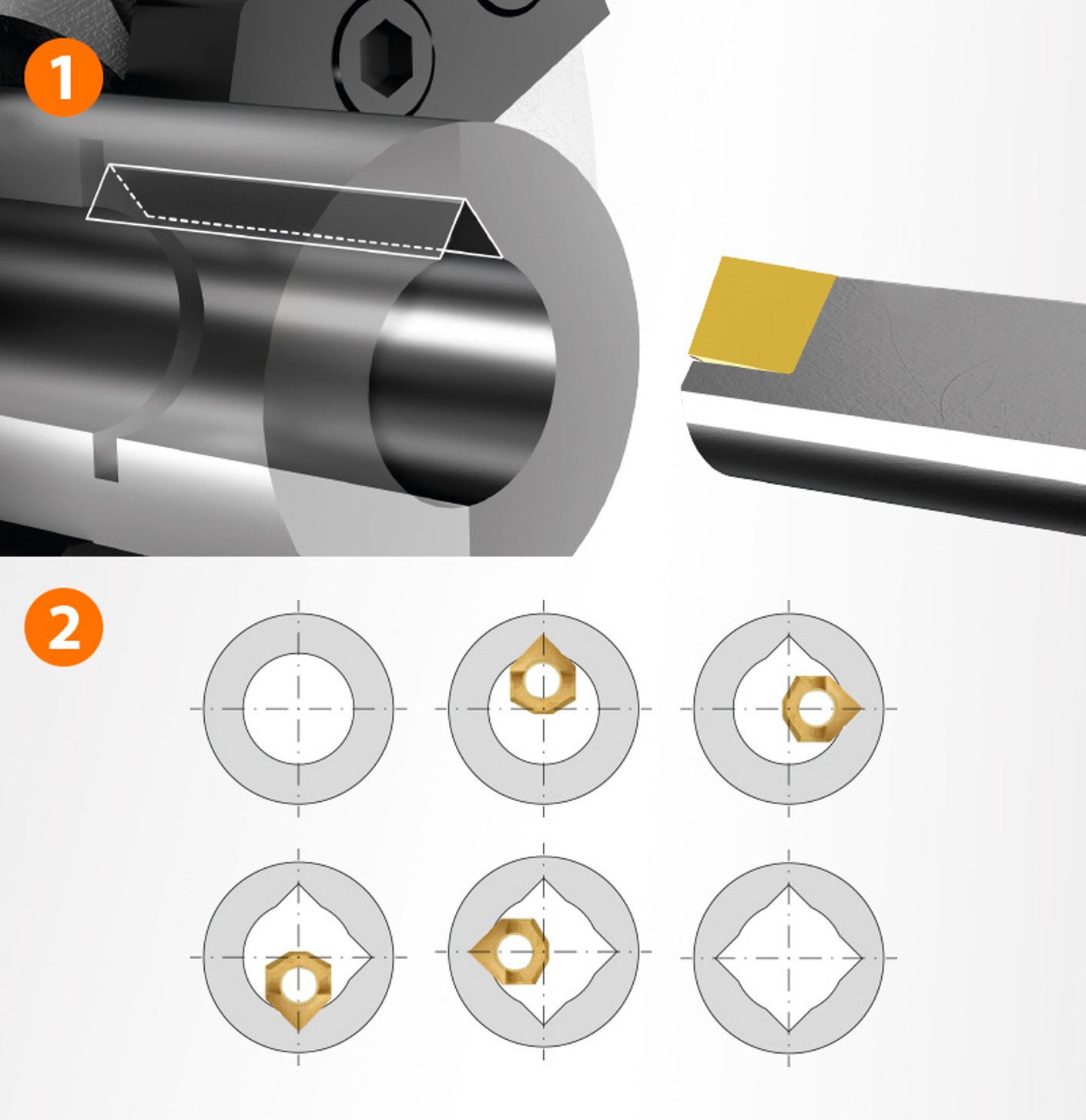

GARANT profile slotting

- Precise profiles - even in materials with high tensile strengths.

- Square procedure: Four 90° steps.

Additional information

More detailed information and guide values as well as information on programming cycles for slotting grooves and profiles can be found in our brochure.

To the brochure GARANT profile broaching and slotting

To the brochure GARANT profile broaching and slotting