Environmental technology in focus – how to handle hazardous substances correctly

Storing hazardous substances places particular demands on workstations and storage. Regardless of whether it's base trays or waste bins, safety cabinets or hazardous substance storage containers – all facilities should comply with legal regulations. In particular, however, they are intended to protect your employees, your plant and the environment in the best possible manner.

How professional environmental technology ensures legal compliance

Legislators regulate the procedure for handling hazardous substances in companies. In Germany, there are currently around 2,000 laws, directives and regulations that deal with the subject. For example, this also includes the German Occupational Health and Safety Act (ArbSchG), the Working Area Regulations (ArbStättV), the German Ordinance on Industrial Safety and Health (BetrSichV), numerous technical rules for hazardous substances (TRGS), the German Ordinance on Hazardous Substances (GefStoffV) and many more.

In order to adhere to these regulations, there are responsibilities (from the managing director and head of department to the safety engineer) with the risk of personal liability. Professional and standardised safety technology eases a lot of this burden, as you are purchasing a lasting guarantee of legal compliance. According to the law, companies have a duty of care towards people and the environment. With the right safety equipment, you can easily comply with this.

Storing hazardous substances – the risk is underestimated

The requirements placed on a hazardous substance store are clearly regulated. Dangerous goods are divided into:

- Water-polluting or environmentally harmful substances (hazard category GHS 1–4)

Storage in containment trays made from sheet metal and plastic (PE) is possible here. - Flammable liquids (hazard category GHS 1–3)

In Germany, storage in plastic trays is forbidden here; sheet metal trays must be used. - Corrosive substances (excluding flammable substances)

They can be stored in plastic trays.

The size of tray required is stipulated depending on the quantity of substance. Furthermore, mixed storage is forbidden for substances that could react with one another.

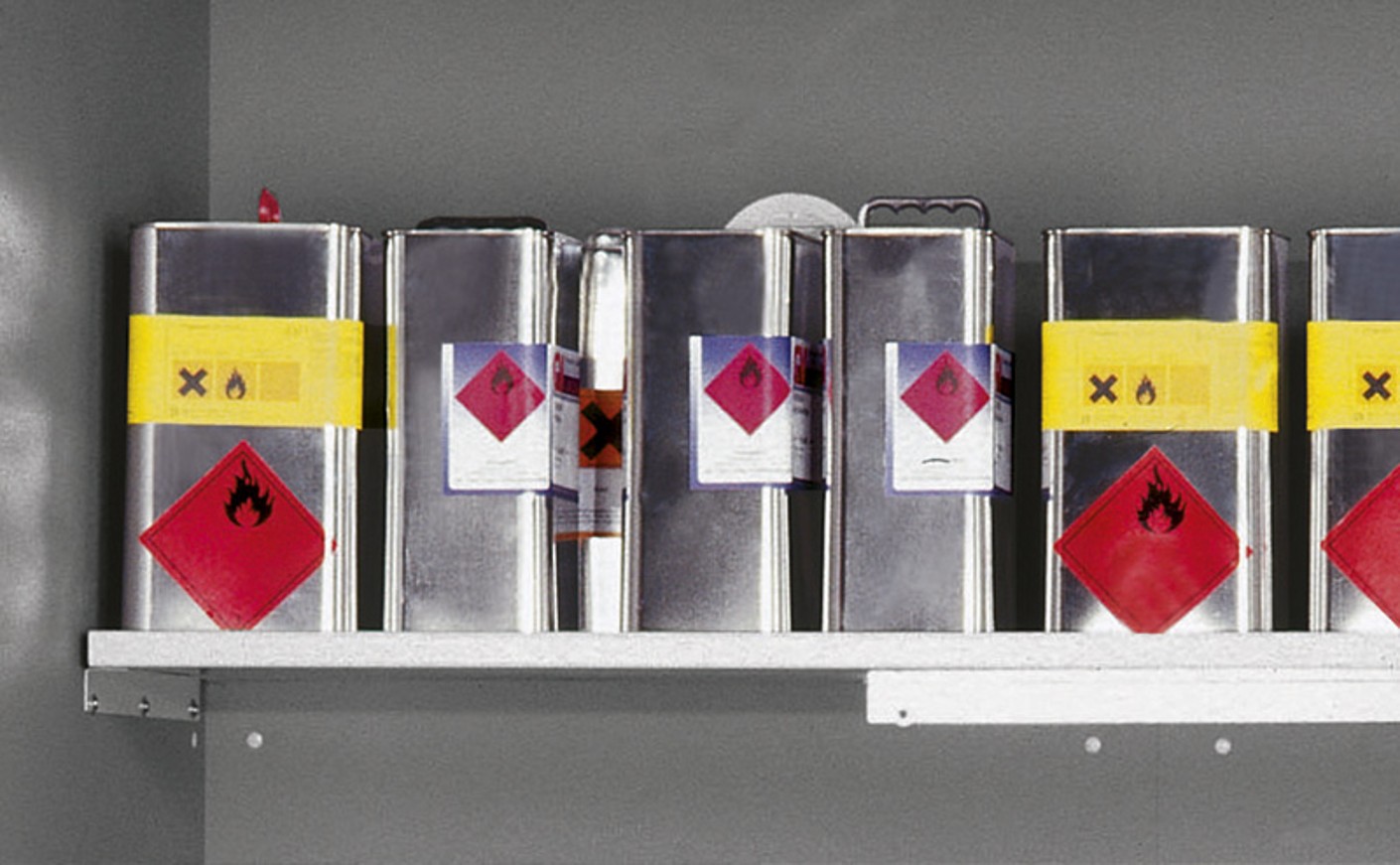

In reality, these rules are often violated. Various hazardous substances are stored next to one another in a disorderly manner without a systematic approach and without base trays; instead of a safety cabinet, numerous containers without labelling of hazardous substances are kept on shelves. This is in no way in accordance with the regulations for environmental technology. In particular, the hazardousness of aerosol cans is underestimated. In the event of a fire, heated and explosive aerosol cans represent a considerable risk to people attempting to escape, rescuers and firefighters.

The safety cabinet – fire protection for flammable materials

Flammable materials should not be stored on open shelves, but rather in a fire-resistant cabinet. A "hazardous materials cabinet" has a high fire resistance time and can be equipped with recirculation filters for escaping vapours.

In general, a distinction is made between two different types. Type 30 can withstand fire for 30 minutes. It is ideal for small and medium-sized companies that only store small quantities of hazardous substances. There must not be any other safety cabinets in the immediate vicinity of it.

This is not the case with type 90. This chemicals storage cabinet meets the highest fire protection level in accordance with DIN EN 14470-1. It is suitable for larger quantities and can withstand fire for 90 minutes. As chemicals cabinets, both types have the required floor-level containment tray and its materials are fire and acid resistant.

The hazardous substance storage container – store large quantities safely

Water-polluting liquids, acids and alkalis or flammable liquids are often present in large quantities in plants, for example in IBC containers or drums. They should also not be stored in garages and warehouses, but rather in special hazardous substance storage containers that meet the regulations for environmental technology.

The advantages to you are obvious here:

- Correct storage of hazardous substances

- Compact storage in a very small space

- Very high safety with minimum investment costs per storage space

In addition to traditional containers for hazardous substance storage in various sizes, there are various special versions:

Water protection container store

You can store containers and pallets on up to 3 storage levels and across 12 m in length. Due to natural ventilation, the water protection container store is suitable for passive storage of flammable substances. For frost-free storage of hazardous substances, this hazardous substance storage container is also available in a thermally insulated design.

F90 fire protection container, concrete

It is intended for storing flammable liquids and toxic or highly toxic substances. The concrete F90 has pallet racking for storing drums and IBC containers, including a containment tray. Technical ventilation and ventilation modules are integrated. It is fire resistant both internally and externally in accordance with F90; this means that it withstands a standard fire for 90 minutes.

Hazardous substance workstations – a fan is not enough

Toxic vapours that can quickly exceed legal limit values at the workstation often occur during decanting, cleaning, bonding or mixing. A small solution for infrequent work with hazardous substances would be to use personal protective equipment such as respirators. However, the toxic or explosive vapours are, nevertheless, still present in the space. A more comprehensive measure is to set up special hazardous substance workstations. They do not only provide a blower, but also suction off all vapours reliably and quickly via an air exhaust. Your employees can complete their work with utmost comfort and without any risk to health. Hazardous substance workstations are available in many widths from narrow to extra wide and are therefore suitable for any plant.

The following elements are available for optimum hazardous substance storage and for working with hazardous substances:

In addition to environmental technology, workstations and storage also include workstation systems, tool cabinets, tool issuing systems, roller cabinets, tool trolleys, storage technology, ladders and platforms and room systems and containers. Find out more about the topics of ergonomics at the work place and the 5S method here. This takes you to the overview.

Ensure legal compliance through expert advice and service

Our expert advisors for workstations and storage won't just find the right environmental technology solutions for your plant – they are also available to you with a comprehensive service network for safety-related consultation. Our experts will be happy to give you information either in person, on the phone or via e-mail.

Request personal consultation

Request personal consultation