{{ name }}

Article no. {{ combinedCodeWithHighlight }}

Article code:

EAN / GTIN:

Manufacturer number:

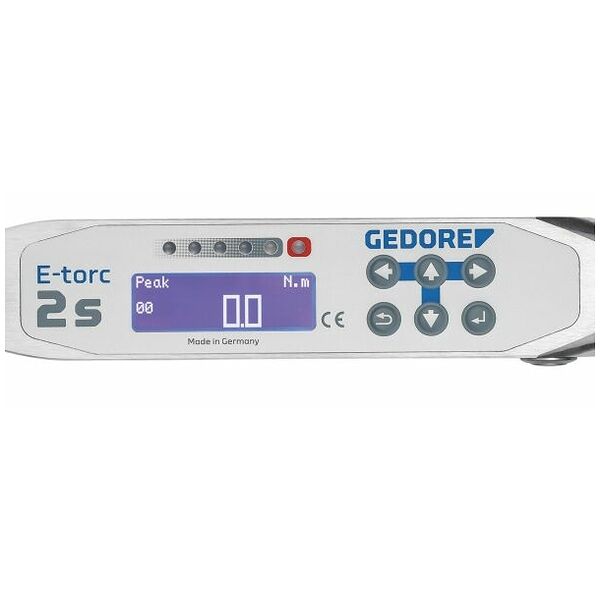

| maximum torque | 25 Nm | |

| Direction of tightening | For right and left-hand tightening | |

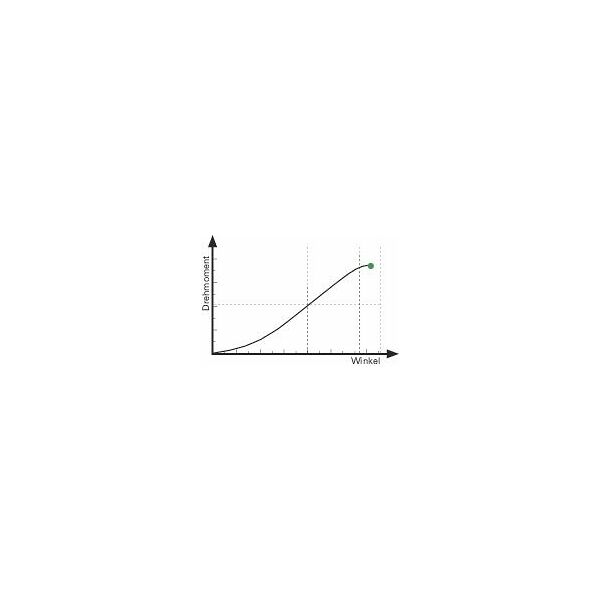

| Torque measuring accuracy | ±1 % | |

| Measuring accuracy rotational angle | ±1 % | |

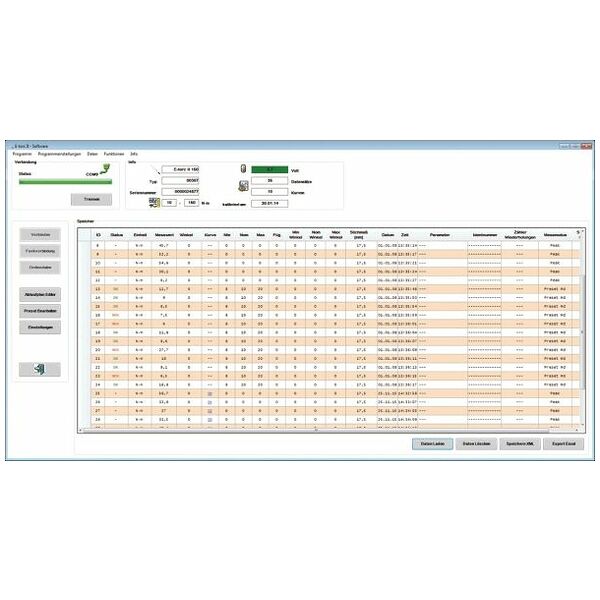

| Interface | Digimatic interface | |

| Test certificate | Manufacturer’s test certificate | |

| Series | E-torc | |

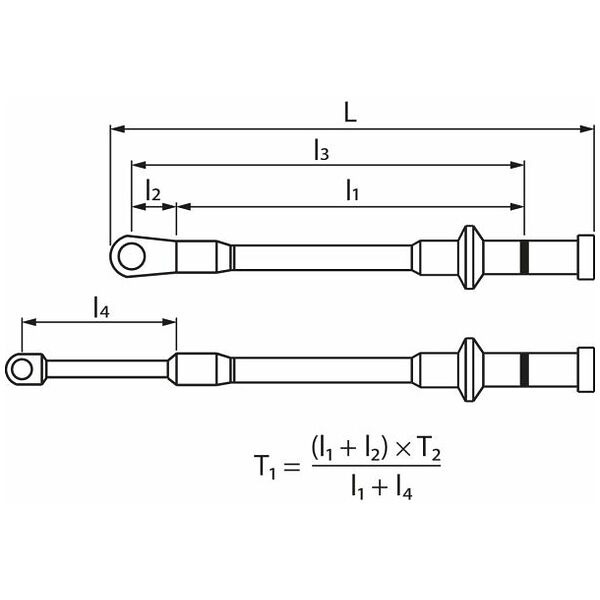

| Overall length L | 347 mm | |

| Torque range | 2 Nm - 25 Nm | |

| Torque range | 1.5 lbfft - 18 lbfft | |

| Resolution | 0.01 Nm | |

| Angular resolution | 0.1 degrees | |

| Weight | 850 g | |

| Square drive | 1/4 in | |

| Display | digital | |

| Release signalling | haptisk; haptisk; haptisk | |

| Trigger principle | Vibration motor | |

| Power supply | Battery-powered | |

| Number of batteries contained | 2 | |

| Battery type | Mignon, AA | |

| Connection format | fixed | |

| Measurement technology | electronic | |

| Data can be recorded | yes | |

| Setting the trigger value | digital, adjustable | |

| Feedback | acoustic signal; displaying; triggering | |

| Reversible reading | Nm; lbfft | |

| Measurement process | Torque; Rotation angle | |

| Adjustable trigger value | adjustable | |

| Standard | DIN EN ISO 6789 | |

| Lever length including factory calibration reference dimension [l3] | 275 mm | |

| Type of product | Torque Wrench |

| Article number | 655007 25 | |

| Manufacturer number | 2795493 |