More than “just” a tool administration system – Hoffmann Group Connected Manufacturing

What could my work look like with Connected Manufacturing?

Which interfaces can be used with Connected Manufacturing?

The portfolio already includes several systems – and more are constantly being added

We currently have all major providers for connections to machine controllers on board – meaning we already cover 90% of the market.

What is Connected Manufacturing?

Your solution when your best worker is on holiday.

Your centralised tool database.

Your complete tools at a glance – across all the different manufacturers. Your workflows recorded digitally.

Your solution when questions about delivery dates put you in the hot seat.

Your digital work schedule with live status. Accessible any time, anywhere.

Your dedicated line between the Production and Work Planning teams.

Your central source of production expertise.

Your (digital) solution when you need to take action.

Your personal adviser which tidies up your tool database and guarantees that tools can be issued 24/7. And that banishes paper from the Production department.

Your solution when it all gets too much for you.

Your link between all important systems. Your source of structure and order. Your Production department that organises itself.

Your employees know the score when it comes to the order – and now you do, too!

It’s so simple to integrate Connected Manufacturing into your production process. In our experience, it only takes around 3 months on average to go from implementing the solution to being able to use it fully in production.

Our consultants will be glad to assist with a holistic support strategy (including a project owner all the way through to live operations) throughout the entire process.

Take advantage of our expert advice

- What exactly is Connected Manufacturing?

- Can I see it live in action beforehand?

Detailed analysis

- How are you currently performing your work?

- Which production processes are required in future?

- Which systems are already in use and need to be integrated?

- What is the condition of your existing machinery?

- What could the first step look like and what is the final vision?

Project preparation

- We work together with you to set up a tool nomenclature system.

- We work together with you to start logging tool serial numbers.

- We prepare the machine interfaces.

- We assist your IT with the security and network requirements.

Commissioning

- We work together with you to build up your centralised tool database.

- We take care of the technical requirements – including with other manufacturers.

- We get the machine connection up and running.

- We put the entire process through its paces with comprehensive tests.

- We draw up a transparent handover report.

Training

- We train your employees so you can get going the very next day.

- Each employee will receive a training certificate.

- We remain by your side once everything is complete – in person or via our helpline.

What steps can and must I take myself when introducing CM?

Define a tool logic.

Prepare the tool data.

Prepare the tools and storage locations.

Obtain the terminal devices.

Establish the IT infrastructure. Integrate the machines into the network.

Enable the interfaces. Integrate the appliance/interface into the network.

Who’s already doing it? Our testimonials

Would you like to find out more?

We’d be pleased to help you.

Use the free Connected Manufacturing callback service here.

How can I get Connected Manufacturing?

I’m interested in the tool administration solution...

... But I need some more information and I’m having difficulty envisaging it all.

... As a customer, what steps do I need to get ready for and what preparatory work is required?

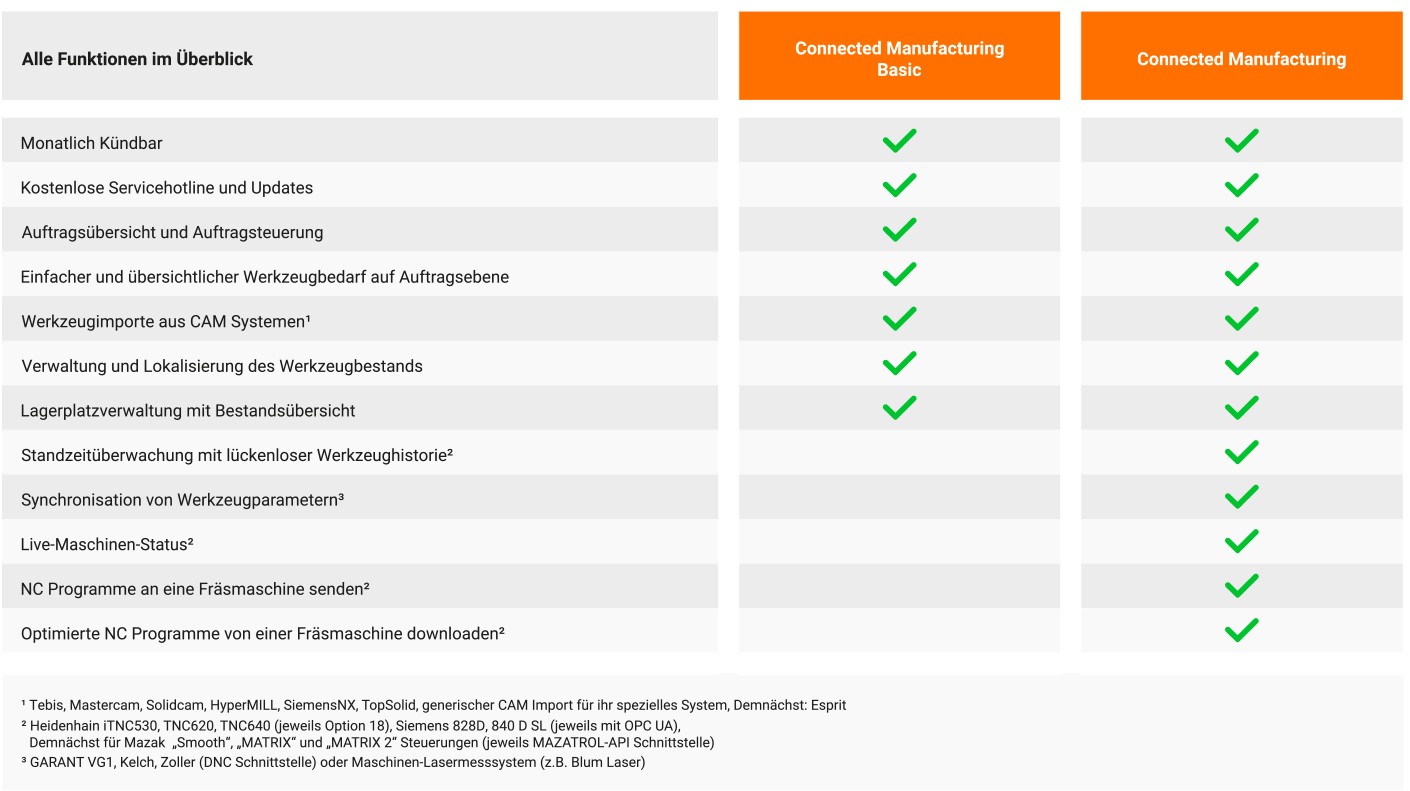

Was unterstützt meine Werkzeugverwaltung:

Keep track and get off to a flying start

Hoffmann Group Connected Manufacturing in a practical test

Company “Karlheinz Hahn – Konstruktion & Entwicklung“ is one of the first pilot customers for Hoffmann Group Connected Manufacturing, which they have been using for several months now. In a short interview Managing Director Karlheinz Hahn talks about his experiences with the new system. Find out more

Digitalise your production process with Connected Manufacturing!

Borries Schüler and Andreas Kastner show you how you can efficiently manage your tools digitally. Using the software Connected Manufacturing enables you to see what is happening in production in real time, which jobs are on the machine and which tools have to be set up. You can digitally retrieve tool and measurement data at any time > Maintain an overview and get started!

Test the introductory package for a month - free of charge!

A solution for any challenge

What are the specific implementation steps?

TRY IT NOW

TRY IT NOW

Consultation with callback service

Consultation with callback service

Download now for free

Download now for free