What are the benefits of using rigid foam inlays or foam inlays?

Using inlays helps you to increase your work productivity and reduce your costs by bringing organisa

Is your workstation sometimes a bit chaotic? Are your machines and tools scattered all over the place? Do you have tools in different variants and sizes that you don’t actually need at the moment? Or perhaps you can’t find the tool you need?

Having a safe, clean and tidy workstation is an important prerequisite for improving your work and production processes. Concepts such as the continual improvement process (CIP), 5S, Kaizen, lean management and others can be helpful.

Other benefits to you

Using rigid foam inlays or foam inlays to organise your workstation provides you with other benefits:

- Spend less time searching for tools: All equipment is clearly marked and labelled, has a dedicated place and can always be found there

- Optimum tool utilisation: Tool duplication is avoided and replenishment times for faulty or old tools are reduced

- More efficient production processes: Shorter set-up times and a fast induction period for new employees help with process optimisation

- Longer tool life: Tools are optimally protected when stored, which prevents damage and defects

- Fewer working hours lost: Optimum organisation of the workstation (ergonomics) helps protect your workers against damage to their health.

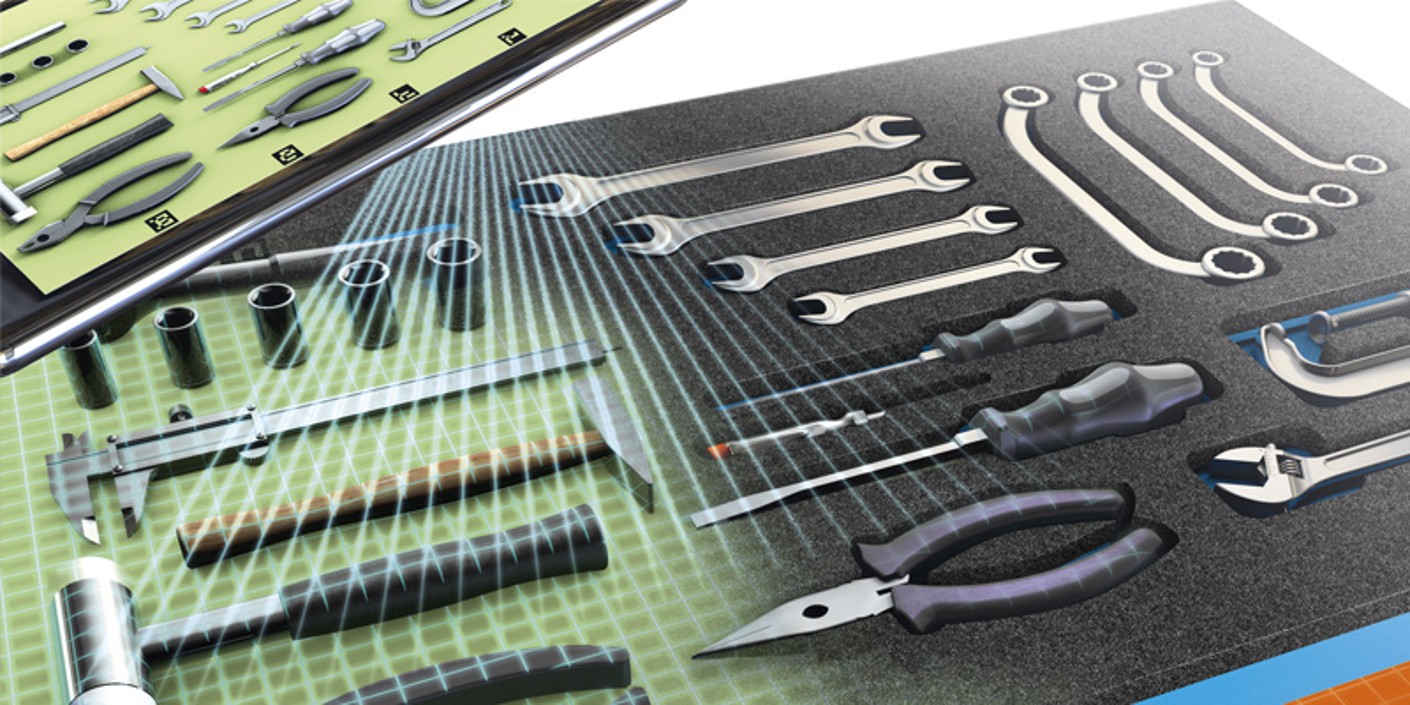

What exactly are rigid foam inlays or foam inlays?

Only once you use custom inlays will your workstations and storage, such as roller cabinets, tool cabinets, workbenches etc. become an efficient modular arrangement system with the following benefits to you:

- Material

The high-quality polyethylene foam (or PE foam) is created using only CO² – no chemical propellants are used. It is very light, fine-pored, water-resistant, oil-resistant and has a long service life.

- Colours

An upper layer in anthracite and a contrast colour underneath immediately indicate if tools are missing or in use.

- Thicknesses and sizes

Different foam thicknesses and sizes are available for filling drawers in roller cabinets and tool trolleys, a tool cabinet, workbench or shadowboard with one or more custom inlays.

- Cleaning

Rigid foam inlays and foam inlays are easy to clean. Simply wash them out with a neutral soap solution using a soft hand brush, and then rinse them off under running water and allow them to dry.

- Electrostatic discharge (ESD)

Special anti-static (ESD) foam is available for storing and organising tools that are needed for work with sensitive components.

For what type of workstation are rigid foam inlays or foam inlays available?

The online configurator

Configure custom inlays yourself, based entirely on your requirements and precisely for your tools!

Our eForm online configurator provides an easy, intuitive and clear way to design your inlays just the way you want them. Possible both as an individual item and in small quantities. Design custom inlays yourself

Do you have any questions? Would you like to arrange a consultation?

The Hoffmann Group provides you with everything from a single source:

- We help you to optimise your workstation

- And provide you with the perfect rigid foam inlays or foam inlays

Additional information

Maximum flexibility and organisation with GARANT GridLine

Thanks to their uniform grid system, the workstations and storage systems from the GARANT GridLine range enable diverse combination and expansion possibilities based on a modular principle. This means that all inlays and dividing materials are suitable for any product from the range, no matter whether it’s a roller cabinet, workbench or tool cabinet. This enables flexible replacement and addition of units, not to mention planning reliability and cost savings.

Contact us now

Contact us now