Saving costs made easy

Optimising processes throughout the entire process chain

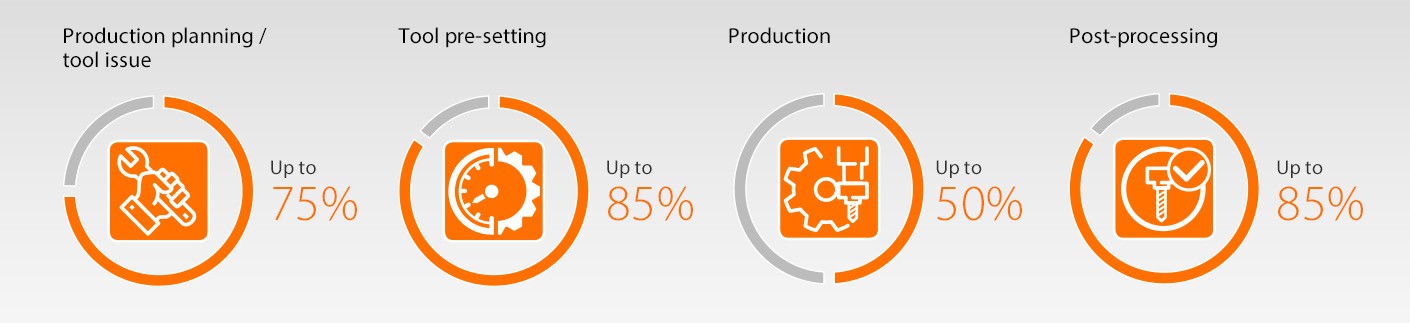

Reducing time and costs by optimising processes: In industry the main focus is on process-based costs. Improve all your processes related to tools and thus significantly reduce your production costs. We will be at your side along the entire production process, from production planning, tool pre-setting and production, right up to post-processing, showing you ways to optimise your processes.

Production planning / tool issue

Simplify your purchasing and production planning processes, an achieve time savings of up to 75%. You can thus reduce costs, speed up processes and make comparison of different tools easier.The GARANT Tool24 goods issuing systems create greater efficiency in procurement and supply, with a comprehensive data-based approach!

Achieve a savings potential of up to 50% in procurement process costs and in stock levels.

At MAN Energy Solutions in Zurich the procurement process for personal protective equipment was speeded-up by 75% when the company introduced the individual issuing system GARANT Tool24 PickOne. As soon as stocks of a product fall below a set minimum level, the system automatically reorders this product. Read more about the process optimisation at MAN Energy Solutions, using the tool issuing system >

More information about the GARANT Tool24 tool issuing system can be found here:

Get production started more quickly with the ToolScout. Quickly find the ideal tool for your application with the ToolScout of the Hoffmann Group. Selected tools can be saved and ordered directly in the Hoffmann Group eShop.

It will help you to optimally plan your production process by additionally providing you with application data as well as information on tools and materials. As the data and results are easy and quick to obtain, you will save an enormous amount of time and thus be able to reduce your production costs.

Find tools now and get started immediatley:

Efficient production - the example of TPC milling

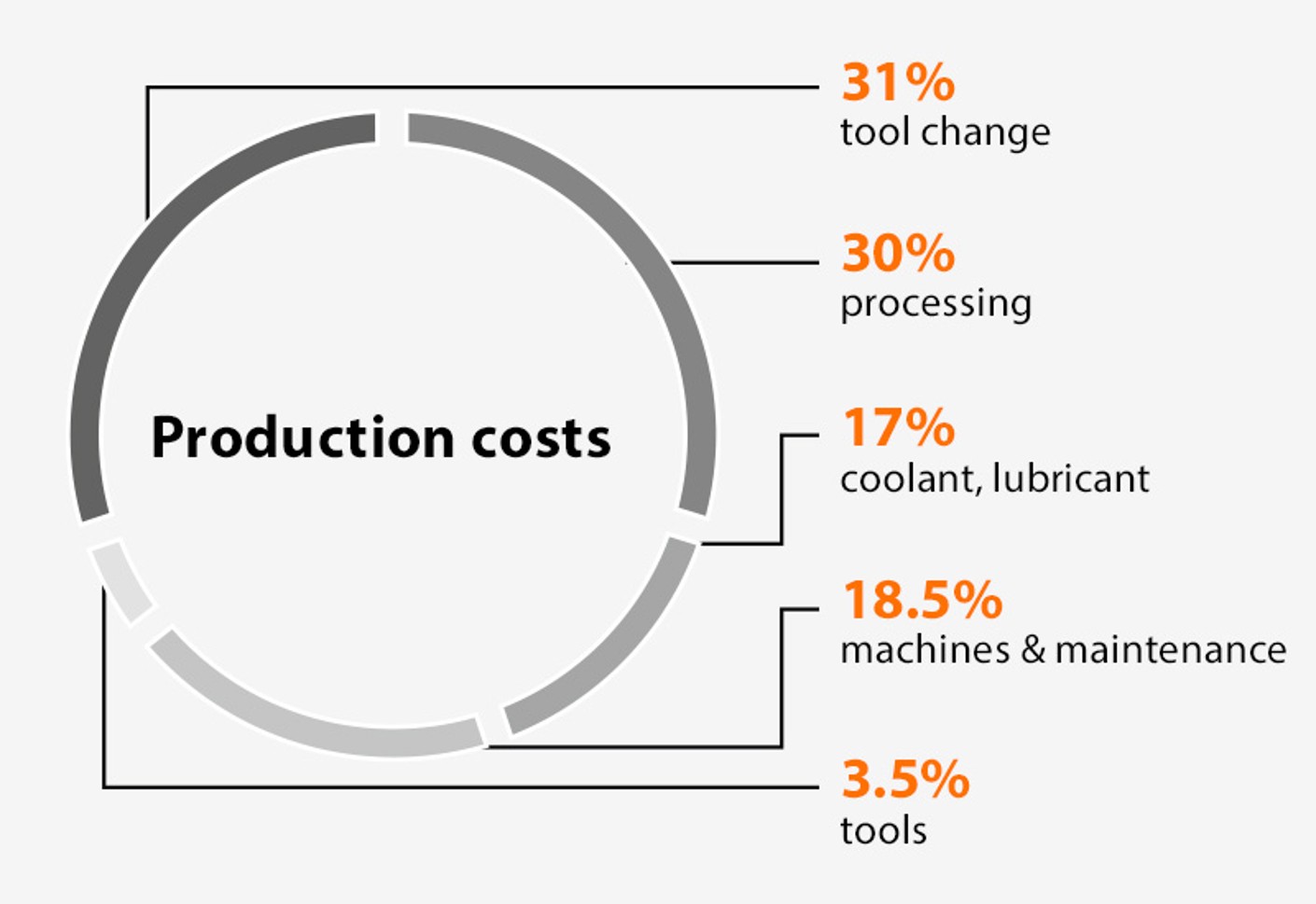

In a modern production environment on average only approx. 3.5 % of the production costs can be attributed to pure tool costs.

The use of efficient manufacturing strategies can have a markedly positive effect on production costs.

Enormous potential for savings through the use of efficient milling processes.

The right milling strategy can significantly reduce processing times: The TPC milling process, when used with suitable CAD-CAM programming, makes it possible to achieve time savings of up to 50 %.

TPC is synonymous with very high metal removal rate, very high dynamic path speed, low cutting force, low wear and high savings potential compared to the conventional strategy.

You can find concrete product data on the GARANT solid carbide milling cutter TPC and information on the trochoidal milling strategy here:

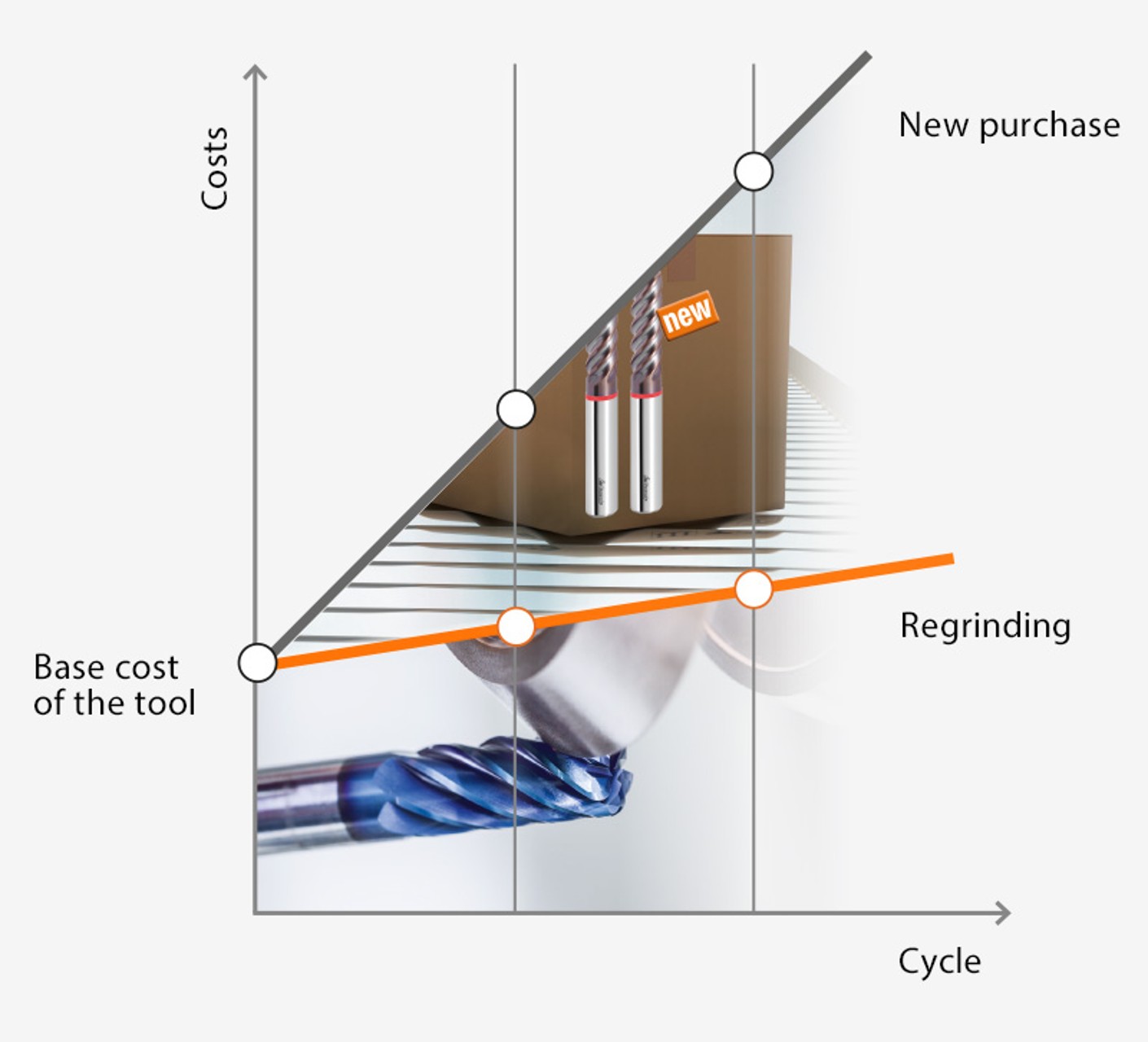

Post-processing - Regrinding service

The longer you can maintain the original quality of your machining tools, the larger your cost savings.

Achieve savings up to 85% with an original regrind of your tools.

Regrinding of your drills or milling cutters will lead to reduced storage and capital costs, higher availability and reduced circulation times, at miximum productivity.

All the facts about our regrinding and reconditioning service: