In top form

Innovation meets high-quality PM substrate and HIPIMS coating technology:

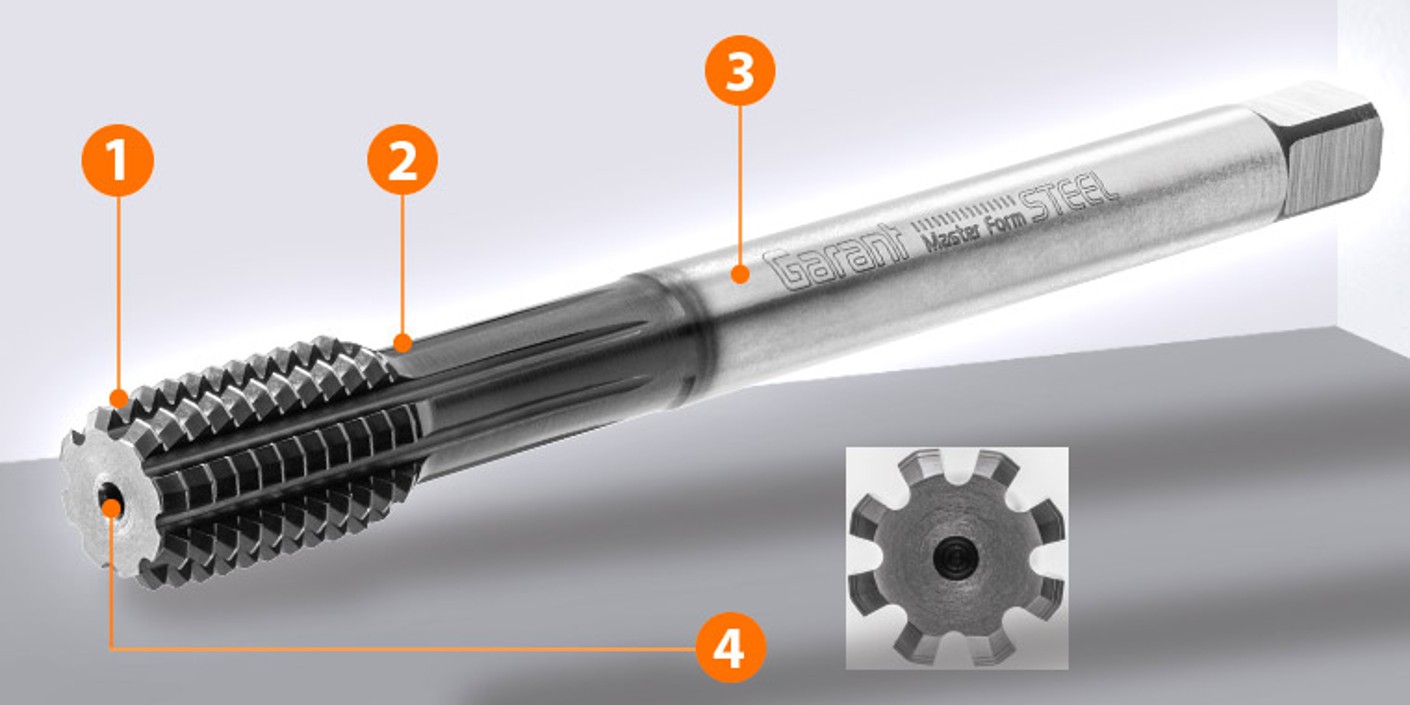

The specially developed polygon geometry on the GARANT Master Form Steel reduces torque forces in the forming process.

An exclusive coating in conjunction with a selected high-performance substrate guarantee a top tool life and performance data.

Our specialist amongst the fluteless taps

GARANT Master Form Steel provides the utmost process reliability, a very long tool life and unique quality.

1. Optimised chamfer:

• Uniform force distribution

• Uniform forming process

2. HIPIMS coating:

• TiALN multilayer coating

• Very smooth surface structure

3. HSS-E-PM tool material:

• Very good wear resistance

• Long tool life

4. Dynamic polygon geometry and increased number of pressure flutes:

• Reduction in the torque

• Improved process reliability

The right application of force – a thread forming process with lower forces required

The torque that arises during thread forming, also often called thread cutting, is often higher than in other processes for producing threads if you take different factors into account. The main factors influencing this are the cold forming suitability of the material, the selected pre-drilling diameter and the lubricant used. Using the new GARANT Master Form Steel fluteless tap, it is possible to process a wide range of different steels. Thanks to the specially developed geometry, the arising forces are reduced and excellent results can be achieved in higher strength and abrasive steels.

Test series in high-alloy tool steel X 155 CrVMo 12-1 (1.2379)

- 500 threads ØM6

- Tapping hole diameter 5.55 mm

- Cooling lubricant 8% (external cooling)

- Thread depth 2.5 X D

- Cutting speed Vc: 12 m/min

Strength: 830 N/mm²

Alloy proportions: 1.55% C; 12% Cr; 1.0% V; 0.7% Mo

-> Maximum torsion is the lowest with the GARANT Master Form Steel.

Greater durability – high wear resistance and long tool life

During the thread forming process, high compressive forces and temperatures act upon the tool and cause tribochemical forms of wear. In addition to the optimised polygon geometry, the very smooth surface of the coating on the GARANT Master Form Steel ensures reduced friction between the tool and workpiece. These advantages counteract the signs of wear and provide an excellent tool life.

Test series in high-alloy tool steel X 155 CrVMo 12-1 (1.2379)

- 500 threads Ø M6

- Tapping hole diameter 5.55 mm

- Cooling lubricant 8% (external cooling)

- Thread depth 2.5 × D