GARANT high performance cutting discs

Highest productivity for steel and stainless steel.

Extremely long service life and quick cutting in practical applications

GARANT cutting discs meet the highest standards for cutting performance, service life, and safety at work.

The thinness of the disc allows very quick cutting with low force and optimum time saving. Clean cut edges, virtually no burrs. New high-performance version using state of the art technology with significant productivity advantages and excellent cutting properties.

- Very high cutting performance due to rough free-grinding side faces.

- Outstanding tool life.

- Version without edge compaction permits improved cutting behaviour from the first cut, with smooth and aggressive cutting behaviour.

- Very little production of dust, noise, and vibration.

- Maximum safety (oSa certification).

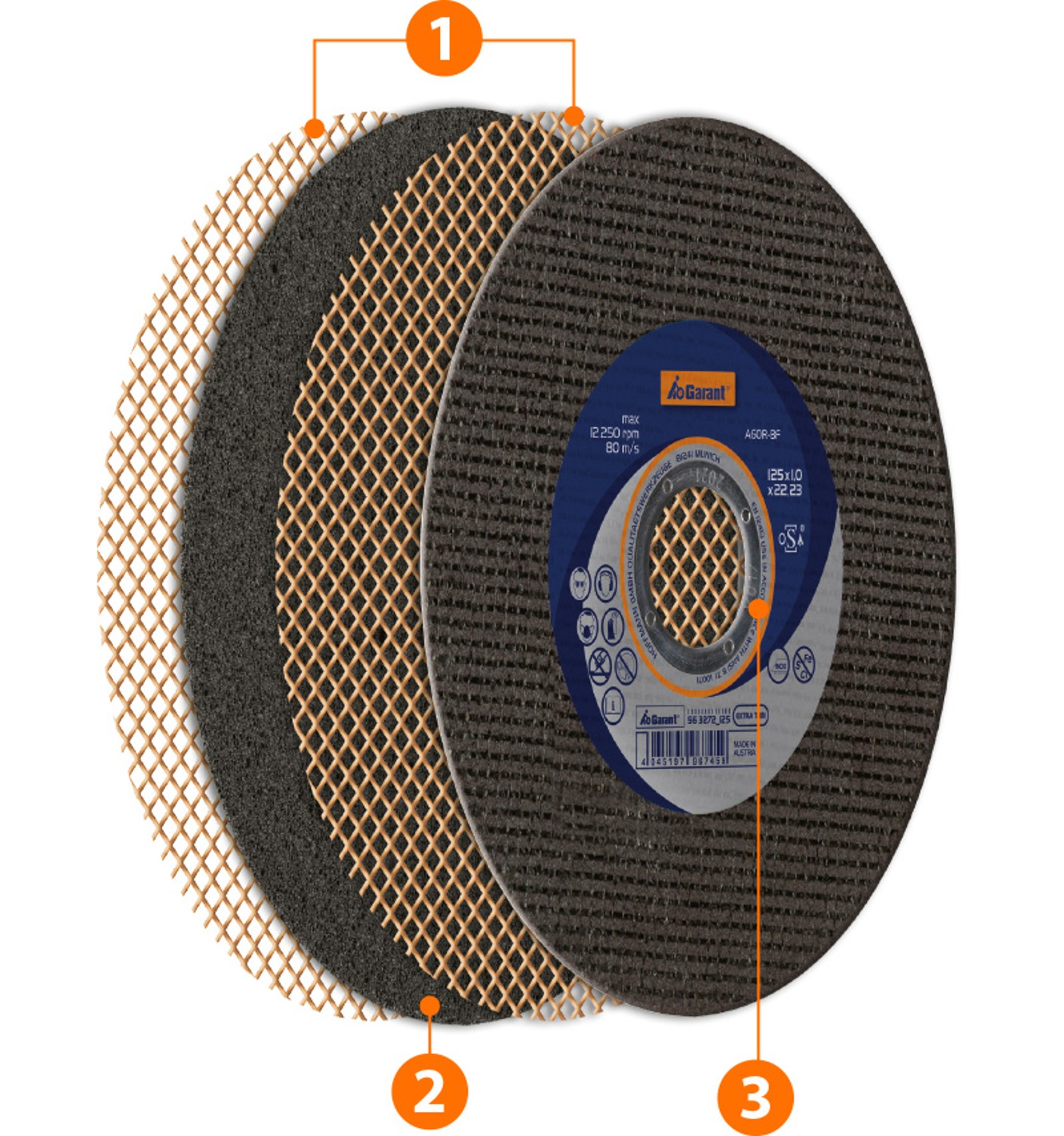

Innovative construction

Newly developed binding system based on full synthetic resin

Only in combination with the newly developed, innovative binding system can the performance of the aluminium oxide abrasive grain be fully utilised. This achieves the optimum balance of grain bonding and fracture release of worn grain.

In practical applications, this means long tool life combined with fast cutting.

- Fibreglass fabric provides for safety and lateral stability

- Abrasive fillers to improve the release properties. Mixture of high-quality aluminium oxides. The binding matrix consists of fillers and phenolic resins

- All important product information at a glance

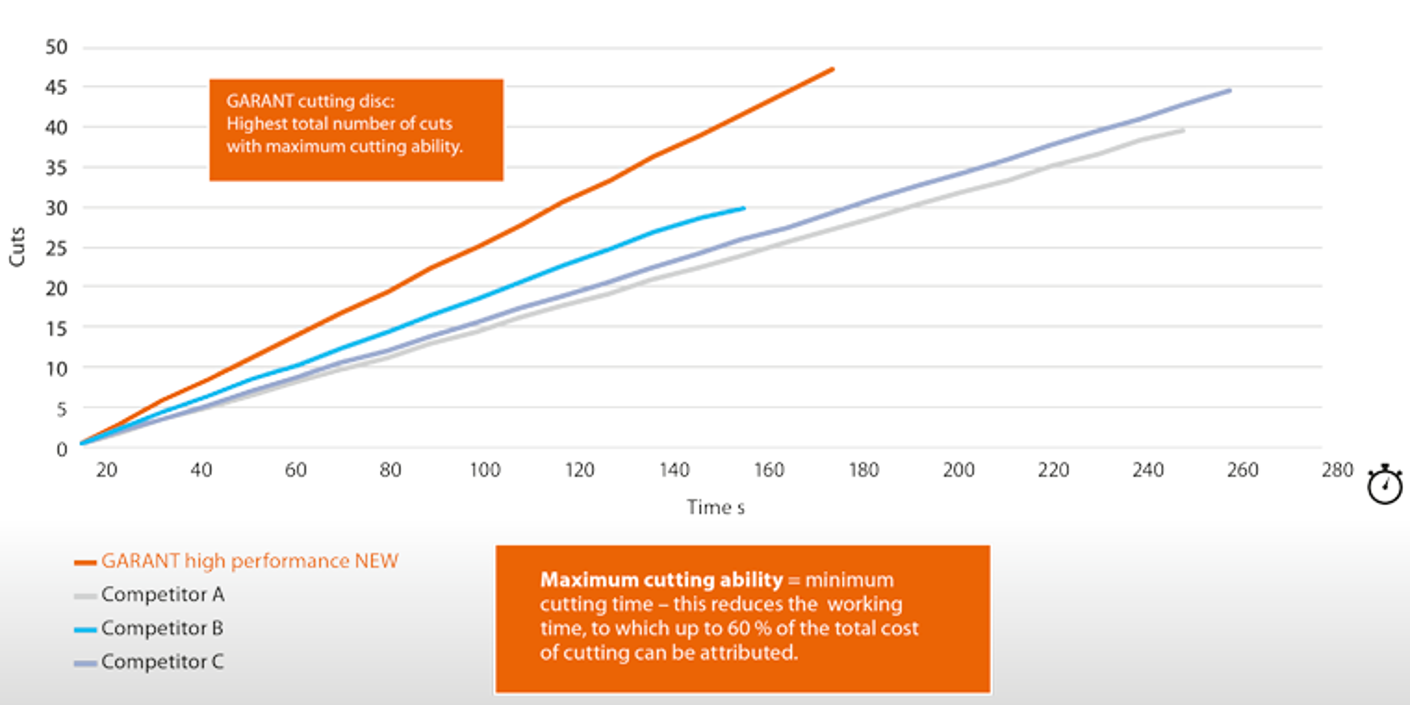

Time and cost savings due to increased total number of cuts

Best total cost analysis due to minimum cutting time and maximum service life.

Do you know your total cost distribution during the cutting process? - The main costs can be attributed to working time. This is reduced significantly by the use of high-performance cutting discs. The GARANT cutting disc cuts more quickly and can make more cuts. It thus helps to reduce the costs for working time and for time needed for disc change.

Service life and cutting time: test result of Ø 125 mm

cutting discs 1.0 mm in a comparison with the competition.

Internal tests on an L-profile workpiece (steel) material thickness 4.0 mm:

The cutting discs were tested down to a final diameter of ⌀ 76 mm. The number of cuts in practice depends on the material and the workpiece condition.

The GARANT cutting disc delivers the highest number of cuts with maximum cutting ability.

Maximum cutting ability corresponds to minimum cutting time. This reduces the working time, to which up to 60 % of the total cost of cutting can be attributed.

GARANT cutting discs meet the highest standards for cutting performance, service life and safety at work.

Number of cuts:

Higher number of cuts - lower tool consumption - reduced tool-changing times → This lowers idle times for disc change and tool costs.

Cutting time:

More separating cuts in a shorter time - highly aggressive, fastest separation → This saves time and labour costs.

Rework:

Better results - low-burr cutting - less heat transfer to the workpiece → This reduces time and costintensive rework.

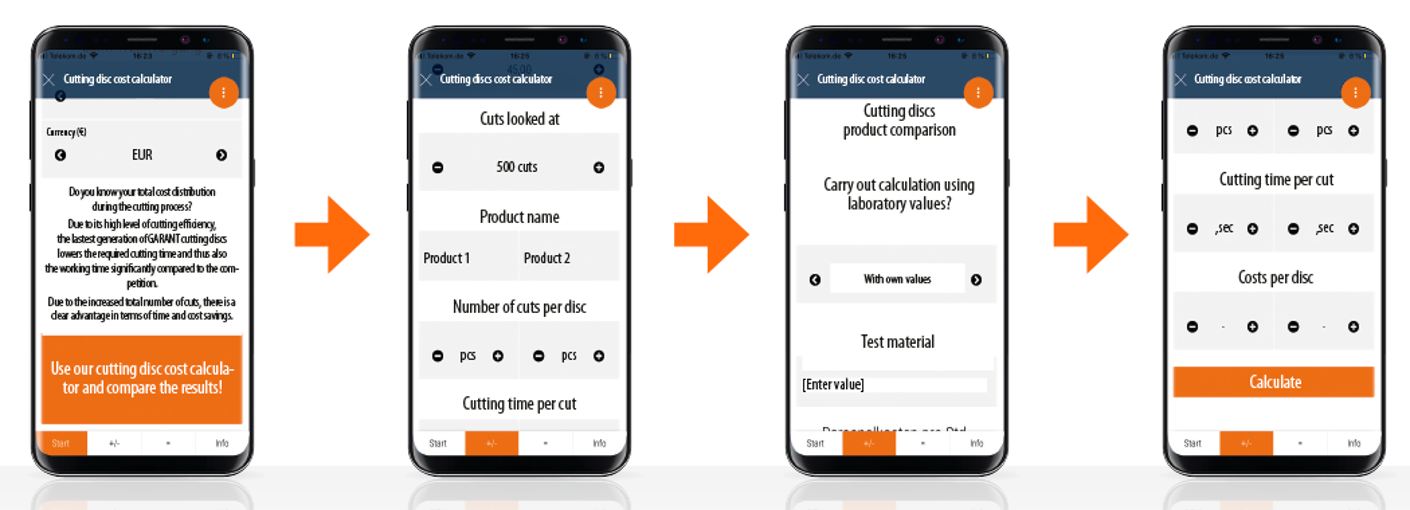

Calculate your savings potential with the cutting disc cost calculator

Use the cutting disc cost calculator of your specialist adviser and compare for yourself!

The cutting disc cost calculator will show you how the total costs for the cutting process are distributed and compare them.

Inputting the number of cuts per disc, cutting time per cut and costs per disc will give you a clear result regarding cutting disc costs, working time costs and costs for changing. You will be able to see your savings potential immediately.